- Home >

- Products

Top Products

-

Two- color airtight food container plastic injection mold

For this type of airtight food container, there are buckles on the side to ensure the tightness and prevent the leakage. Some buckles are made separately, however we made the two-color lid and buckles as one-piece. Therefore, a two-color lid and a body are one complete set, which makes product be lighter and simple. The weight of lid is 33g (25.5g for PP, 7.5g for TPE), and the body is 34g (33.3g for PP, 0.7g for TPE). On the other hand, producers can avoid on purchasing mould for buckles, which can save time and cost.

Read More -

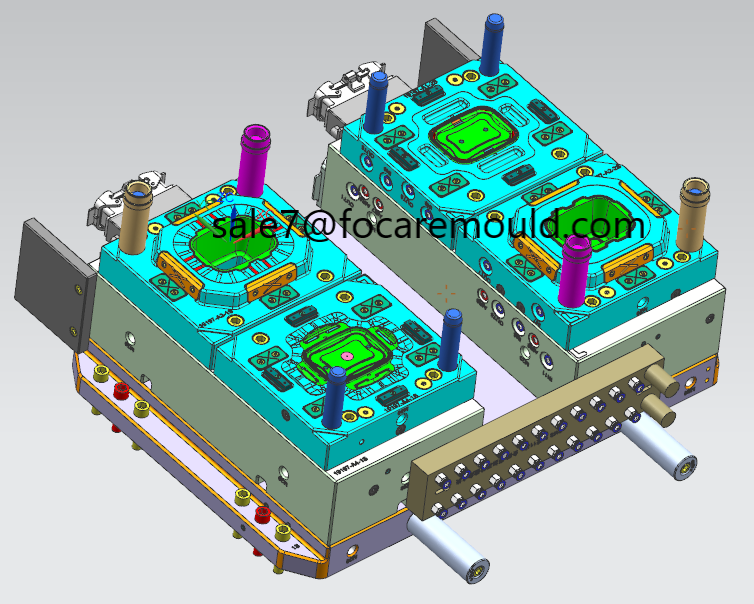

Refrigerator drawer plastic injection mold

Refrigerator drawer belongs to large-scale production plastic mold and requires high standard, so single cavity injection molding process and point gate hot runner are used in injection molding. For the parting surface of the drawer, it determines the structural form of the whole mold, so this design adopts the injection mode of the double parting surface to achieve the stability of the whole refrigerator drawer structure.

Read More -

Portable & Collapsible Pet Food & Water Bowl Double Color Plastic Injection mould

The bowl made of this PP + TPE material has the following advantages: 1. Folding design, easy to go out. 2. Non-toxic plastic, safe, durable and easy to clean. 3. Hanging buckle design, can be hung on the cage or pet stroller. 4. Bottle hanging design, which can be installed on the water bottle to make the dog eat better.

Read More -

Plastic paint bucket injection mold

There are several methods to test plastic paint buckets: 1. Airtightness test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, the bucket should be dumped. The lid should not fall off or leak. 2. Push-down test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, stack three buckets together, tilt them and let the buckets fall; the bucket lid cannot be opened. 3. Drop test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, drop it at an inclined angle of 45 ° at the bottom of the bucket at a height of 80cm. The lid cannot be separated from the bucket, and the bottom of the bucket must not be broken. 4. Special test: After assembling the matching lid to fill the bucket with 80% of water, stack 4 buckets without deformation for 7 days. 5. Side leak test: Fill the bucket with 80% of water and leave to stand for 30 minutes without leakage; turn to the opposite side for 30 minutes without leakage.

Read More -

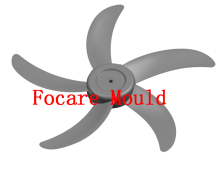

Plastic fan blade injection mold

The whole structure has the following advantages: 1. The rigidity of molding products is good. 2. mold is easy to be assembled and disassembled. 3. The number of mold parts is small. 4. There are few parting marks on the surface of the product. 5. The external dimension of the mold can be reduced.

Read More -

Hair dryer plastic injection mold

Focare mould adopts customized mould base design, which greatly improves mould production efficiency. According to the material of the hair dryer product, the mould core part and cavity part are made of high-quality S136 steel, which has excellent corrosion resistance and polishing performance. In the process of processing and hardening, it has good dimensional stability and can ensure the assembly performance of all parts of the product.

Read More -

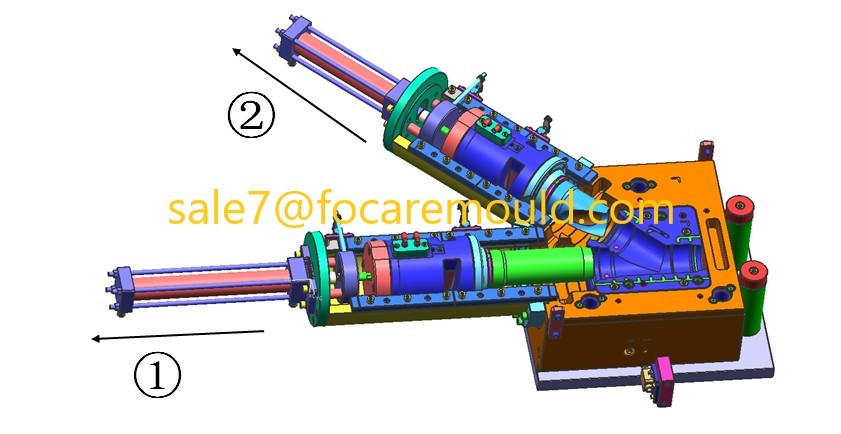

Plastic Pipe Fitting Plastic Injection Mould

To make sure the pipe fitting plastic injection mould has the highest efficiency, the mould will need careful design and calculation for gears. The cooling channels also should be well-designed to reduce cycle time and improve productivity. Below are the movements of D125 Y Pipe Fitting Mould: 1. Mould open. 2. The second cylinder move. 3. The first cylinder move. 4. Ejector bars drive the ejector plate and eject product. 5. Ejector pins return due to the springs. 6. The first cylinder return. 7. The second cylinder return. 8. Mould close.

Read More -

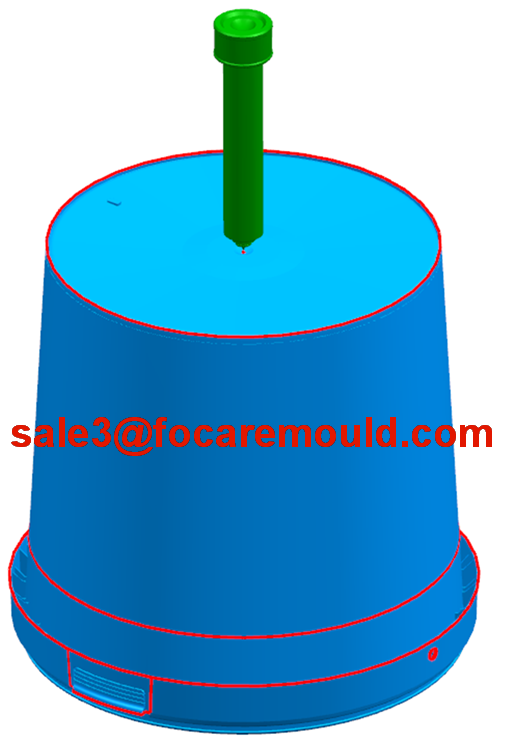

Classical Plastic Flower Pot Injection Mould

The shape of the flower pot can be customized according to the customer's needs. If you are interested in the flower pot mold, please contact us. We can design the ideal product shape for the customer, and carry out mold design, as well as professional mold processing and production, and testing. Stencil. We have a set of high-precision CNC machines, and we are proud of our ability to make high quality plastic injection molds. Providing plastic injection molds with the highest CP value and creating a win-win situation has always been our goal.

Read More -

Safety Protective Goggles Plastic Injection Molds

Our Mold Structure design advantage: 1. There is a spring block in the middle of the cavity, which is ejected at the same time when the mold is opened. 2. When the mold is opened, the core 2 slider will slide away from the product at the same time, and then rely on the middle top block to release the product. 3. In addition, the cavity, core, and slider are all inlaid, which facilitates processing and subsequent maintenance.

Read More