- Home

- >

- Products

- >

- Household Mold

- >

- Two Color Houseware Mold

- >

- Double-Color Plastic Dustpan Injection Mold

Double-Color Plastic Dustpan Injection Mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

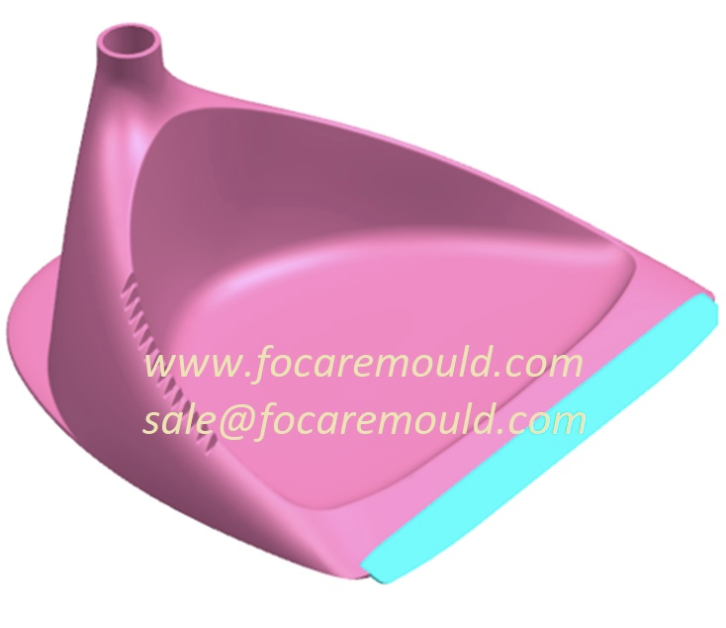

Most of dustpans are made with soft edge to capture more dust, which touches floor closely.

The plastic material of main body for dustpan generally is PP, soft edge is TPE or soft PVC. In order to save investment each machines and molds, the conventional dustpans are molded with PP at the first injection, then made over molding with TPE or soft PVC at the second process.

Now, all the production costs are rising up, including labor cost, rental expense, plastic material and so on. Moreover, the output is less and defectives are higher for making 2-step injection molding. Double components injection molding in one step become more popular.

Detail information of two color 2k dustpan plastic injection mold

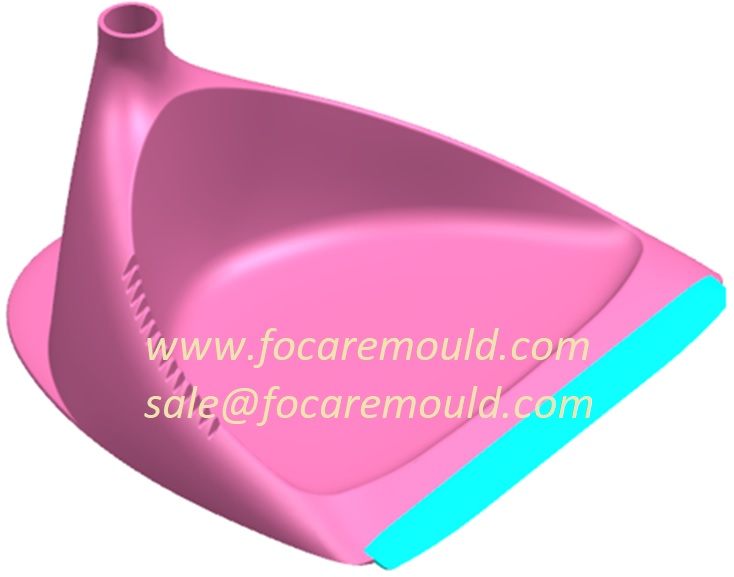

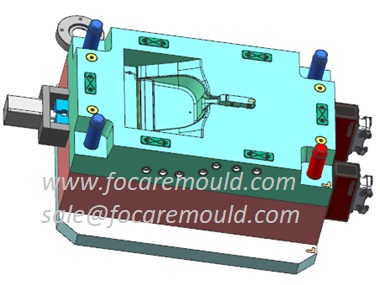

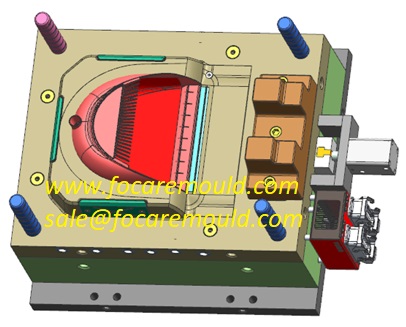

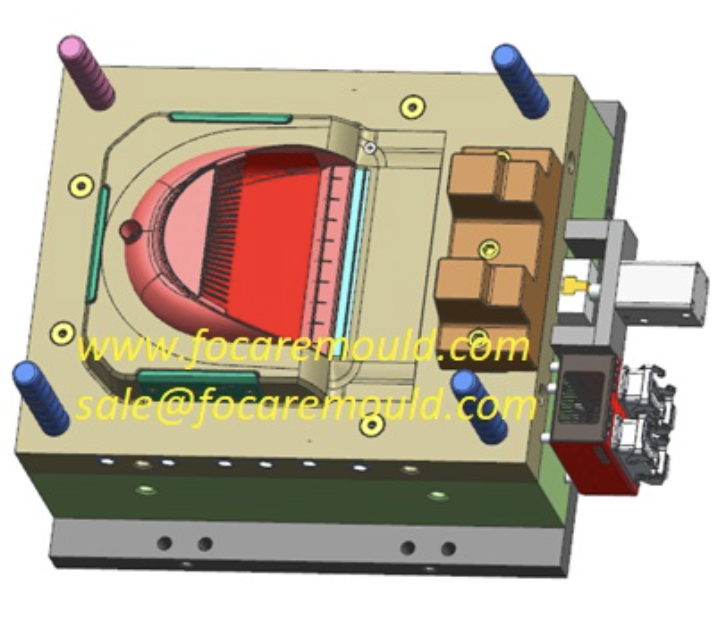

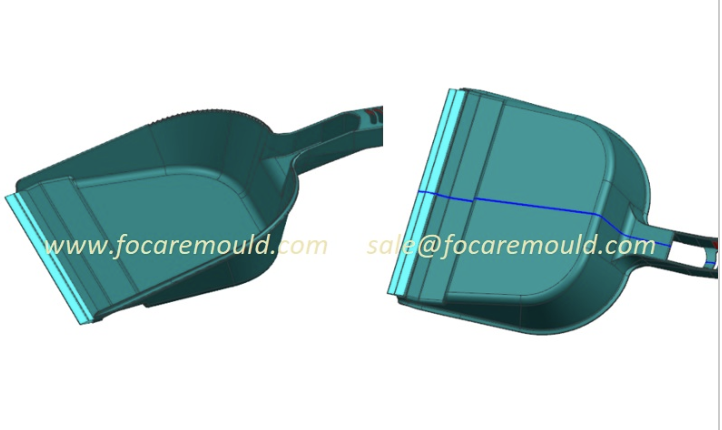

Two color 2k hand dustpan plastic injection mold

Product Material: PP+TPE

Mould Cavity: 1+1

Hot Runner system: 2 tips YUDO HR

Mould Steel: Germany P20 with HRC 30-33

Mold dimensions: 610 X 860 X 555mm

Mold size: 1356 kg

Suggested machine: FCS FB-260R

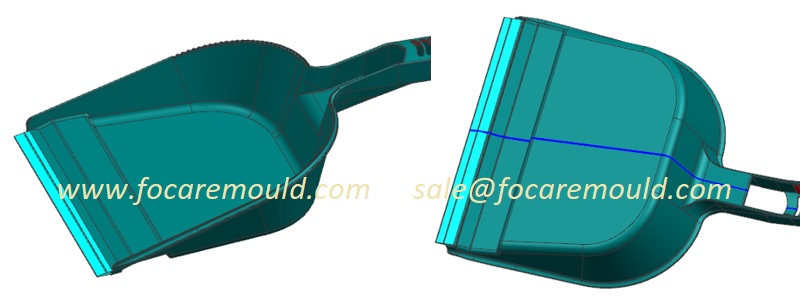

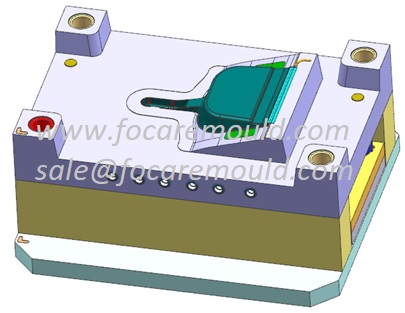

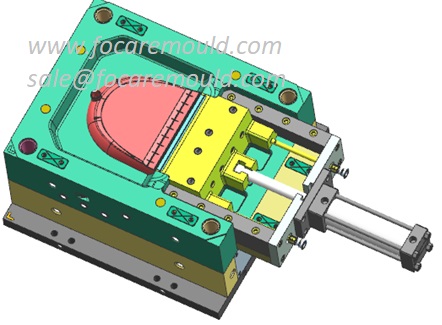

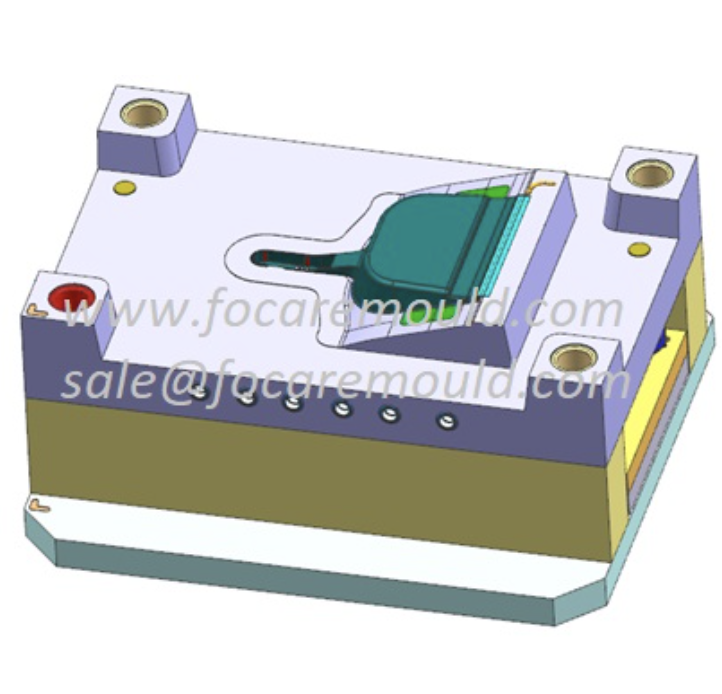

Two color 2k floor dustpan plastic injection mold

Product Material: PP+TPE

Mould Cavity: 1+1

Hot Runner system: 2 tips YUDO HR

Mould Steel: Germany P20 with HRC 30-33

Mold dimensions: 600 X 730 X 571mm

Mold size: 1368 kg

Suggested machine: FCS FB-260R

Most of dustpans are made with soft edge to capture more dust, which touches floor closely.

The plastic material of main body for dustpan generally is PP, soft edge is TPE or soft PVC.

In order to save investment each machines and molds, the conventional dustpans are molded with PP at the first injection, then made over molding with TPE or soft PVC at the second process.

Now, all the production costs are rising up, including labor cost, rental expense, plastic material and so on. Moreover, the output is less and defectives are higher for making 2-step injection molding.

Double components injection molding in one step become more popular.

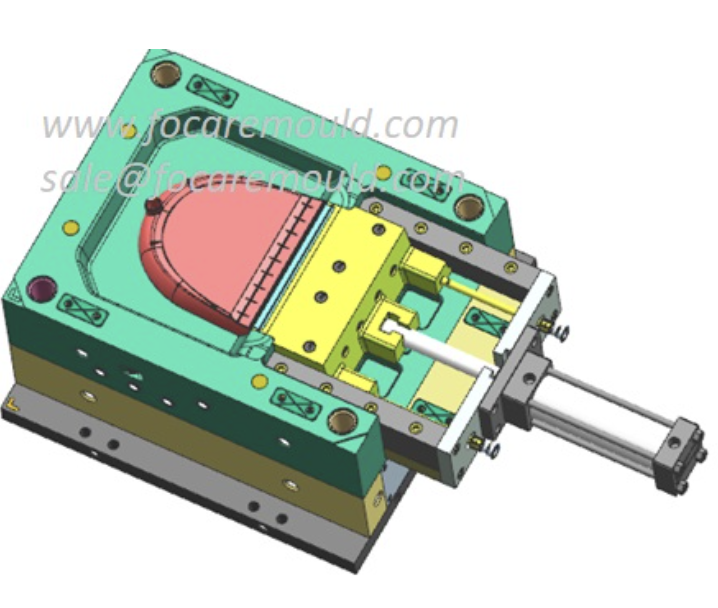

Double Injection is known as 2 materials molding or two-color molding, is an innovative manufacturing process to produce complicated molded parts from two different materials or two color.

Through a highly precise double color or double component mold design and injection mold machine, make high-end double color or double component at one-step injection molding.

Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond.

The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries.

It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

Focare Mould is China professional multi shot mold manufacturer,china mold maker, multi shot injection molding expert.

We can offer you high quality bi material double component two color 2k hand & floor dustpan plastic injection mold.

If you want to make a high quality bi material double component two color 2khand & floor dustpan plastic injection mold, welcome to contact us.

Our professional team will alway give you more information about two color 2k hand & floor dustpan plastic injection mold .

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services