-

TPE Injection Molding Guide | China TPE Mold Maker – Focare Mould

Read More -

PP Injection Molding Guide | China Mold Maker | Focare Mould

Read More -

Case Study: Two Color Flip Top Cap Mold

Read More -

Your Trusted Partner — Focare Mould

Read More -

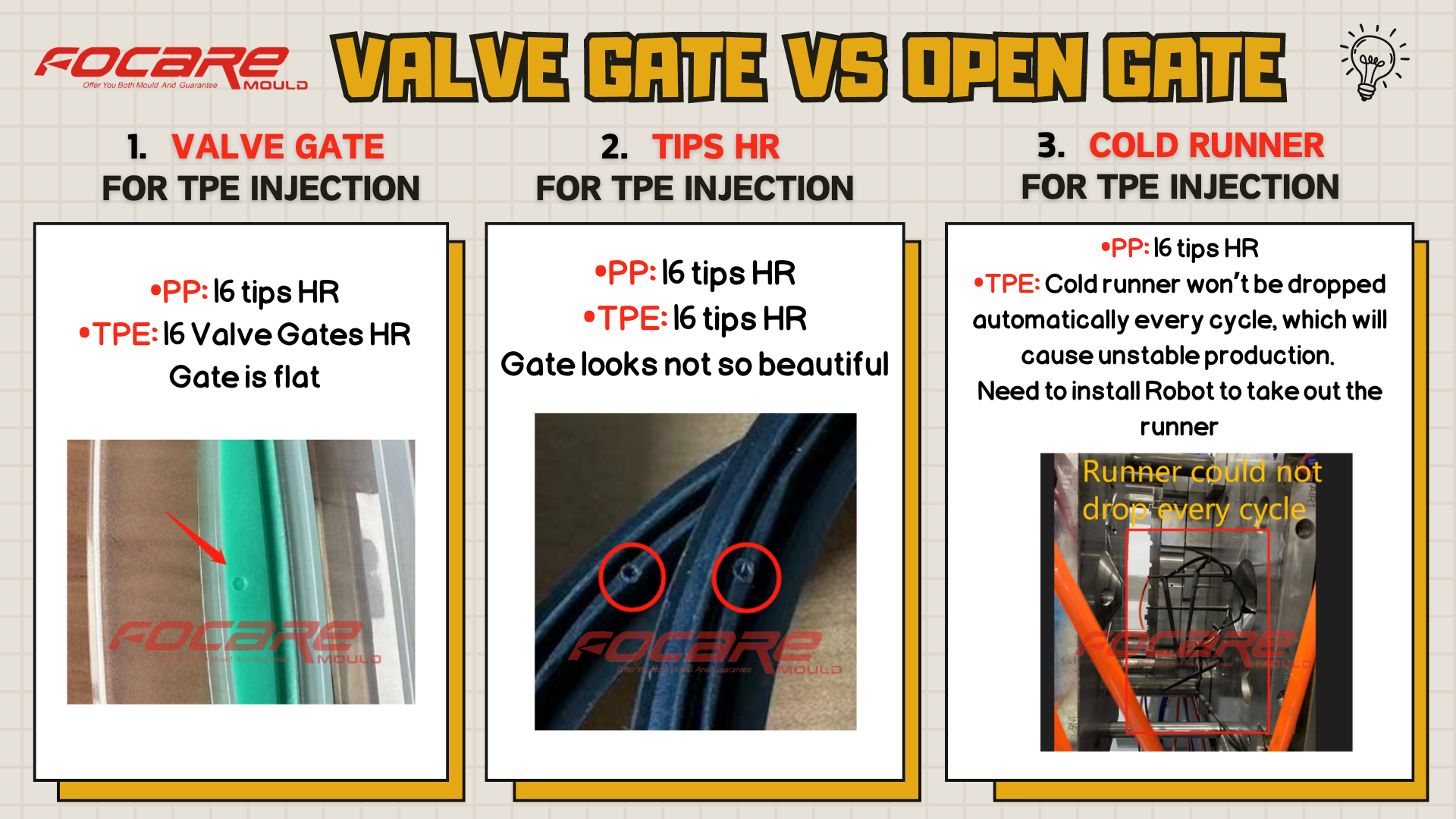

Valve Gate vs Open Gate in Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. Among the various components and technologies involved in injection molding, the gating system plays a crucial role in determining the quality and characteristics of the final product. Two primary gating methods are valve gate and open gate systems. Understanding the differences between these two systems is essential for selecting the appropriate method for specific applications.

Read More -

Application of (Becu) beryllium copper in plastic mould

Beryllium copper Becu is often used in plastic injection molds due to its unique combination of properties that make it well-suited for this application.

Read More

Please feel free to give your inquiry in the form below.

We will reply you in 24 hours.