- Home

- >

- Products

- >

- Household Mold

- >

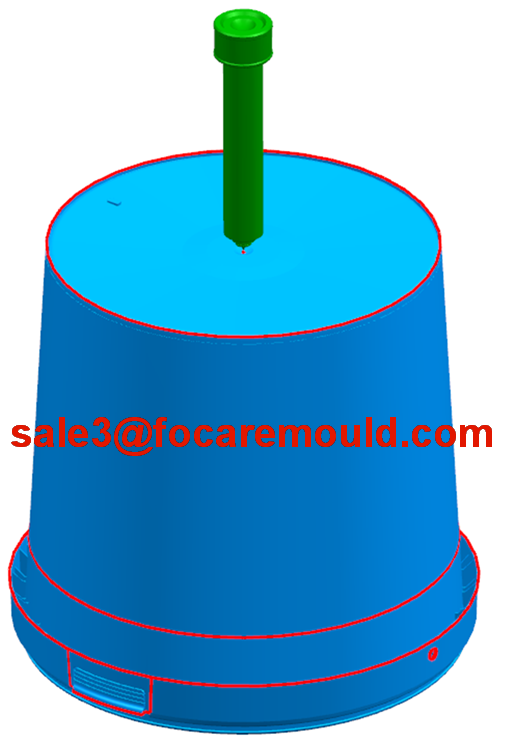

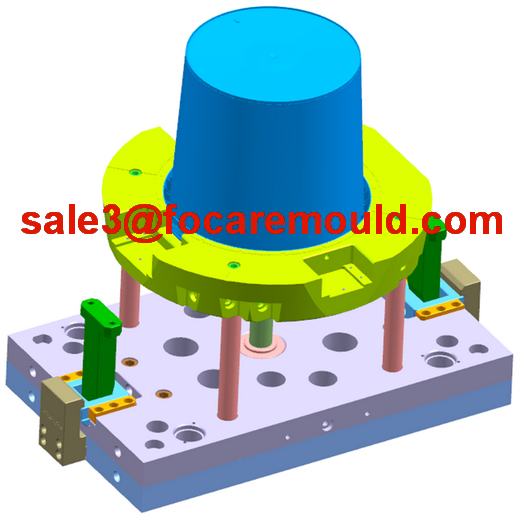

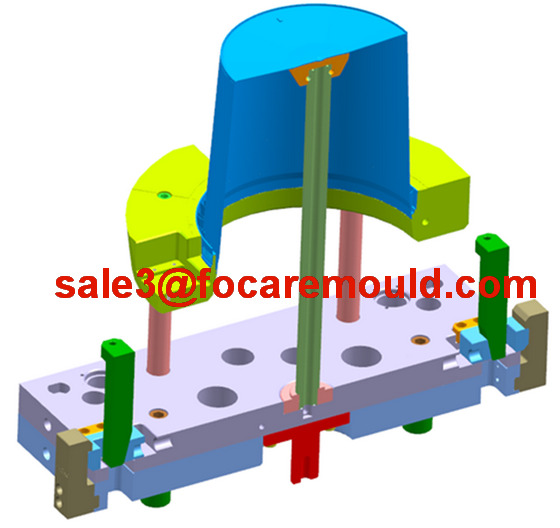

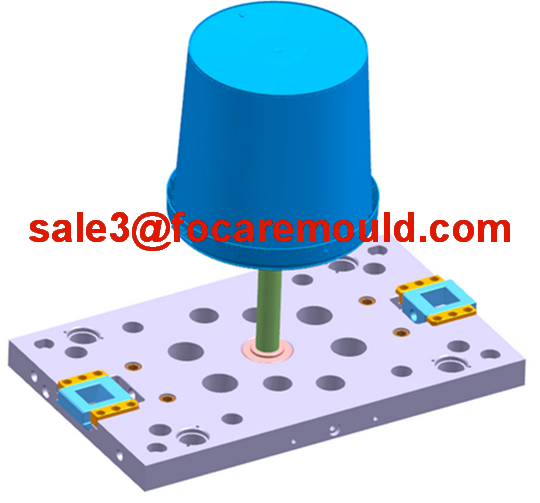

- Plastic paint bucket injection mold

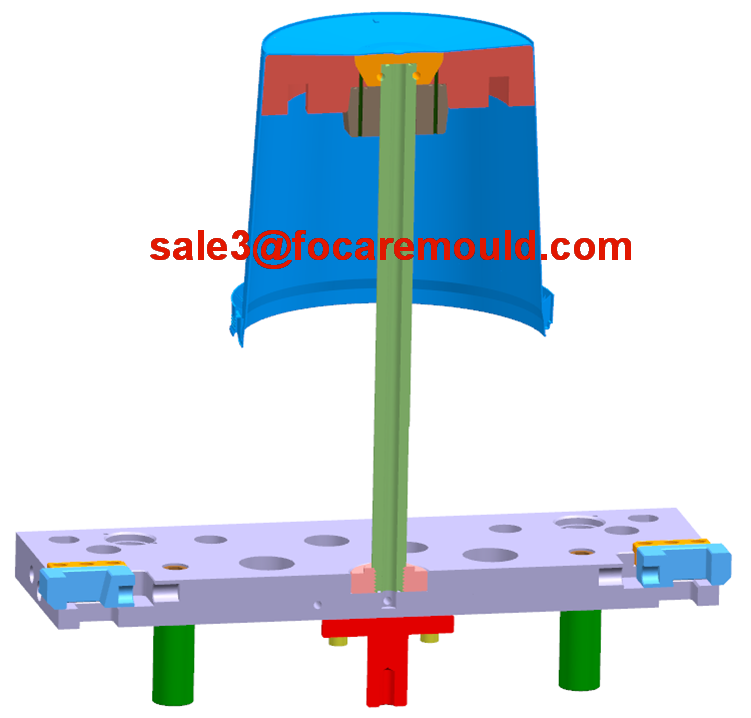

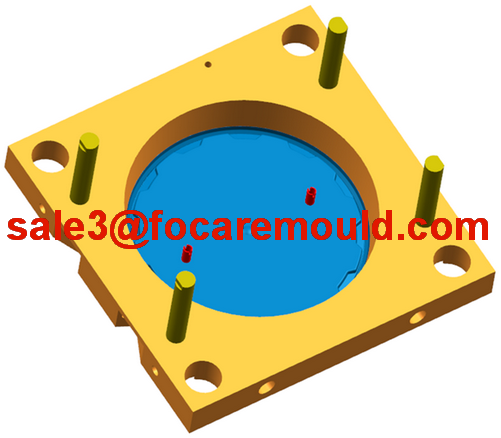

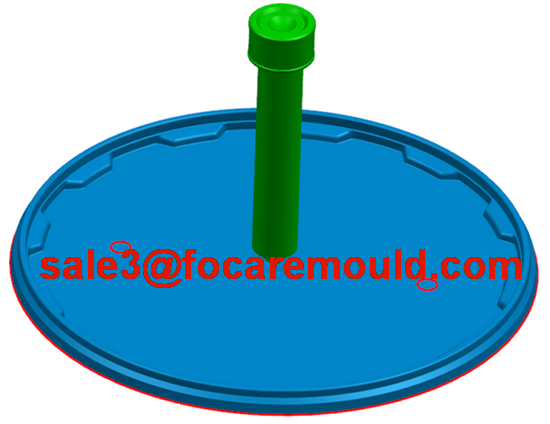

Plastic paint bucket injection mold

There are several methods to test plastic paint buckets:

1. Airtightness test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, the bucket should be dumped. The lid should not fall off or leak.

2. Push-down test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, stack three buckets together, tilt them and let the buckets fall; the bucket lid cannot be opened.

3. Drop test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, drop it at an inclined angle of 45 ° at the bottom of the bucket at a height of 80cm. The lid cannot be separated from the bucket, and the bottom of the bucket must not be broken.

4. Special test: After assembling the matching lid to fill the bucket with 80% of water, stack 4 buckets without deformation for 7 days.

5. Side leak test: Fill the bucket with 80% of water and leave to stand for 30 minutes without leakage; turn to the opposite side for 30 minutes without leakage.

Due to different market demands, there are many types of plastic paint buckets, and their shapes, materials, sizes, and appearances are also different.

The material of the plastic paint bucket can be virgin or recycled material of PP, PE or HDPE, depends on the function requirements for the plastic paint bucket.

The shape of the plastic paint bucket can be round, oval, square, rectangular, etc. You can also use IML or screen printing for decorating the plastic paint buckets.

Although there are so many types of plastic paint buckets according to the plastic material, bucket shape, and decoration. The most important point for making a good plastic paint bucket is the testing for the finished products.

There are several methods to test plastic paint buckets:

1. Airtightness test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, the bucket should be dumped. The lid should not fall off or leak.

2. Push-down test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, stack three buckets together, tilt them and let the buckets fall; the bucket lid cannot be opened.

3. Drop test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, drop it at an inclined angle of 45 ° at the bottom of the bucket at a height of 80cm. The lid cannot be separated from the bucket, and the bottom of the bucket must not be broken.

4. Special test: After assembling the matching lid to fill the bucket with 80% of water, stack 4 buckets without deformation for 7 days.

5. Side leak test: Fill the bucket with 80% of water and leave to stand for 30 minutes without leakage; turn to the opposite side for 30 minutes without leakage.