-

Plastic Pipe Fitting Plastic Injection Mould

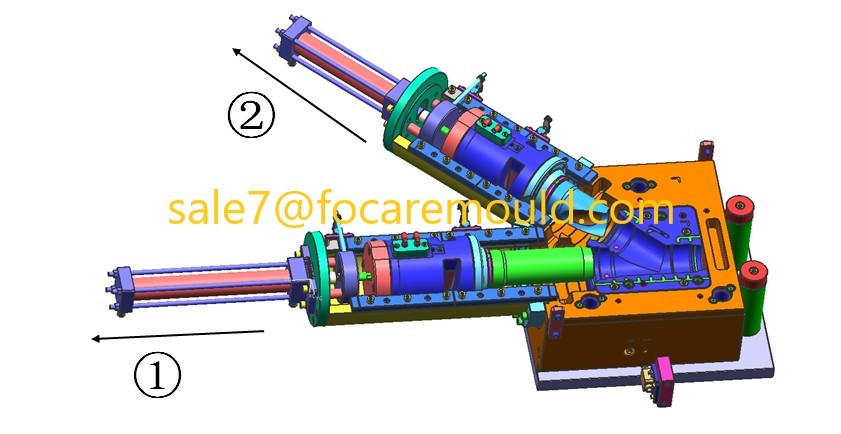

To make sure the pipe fitting plastic injection mould has the highest efficiency, the mould will need careful design and calculation for gears. The cooling channels also should be well-designed to reduce cycle time and improve productivity. Below are the movements of D125 Y Pipe Fitting Mould: 1. Mould open. 2. The second cylinder move. 3. The first cylinder move. 4. Ejector bars drive the ejector plate and eject product. 5. Ejector pins return due to the springs. 6. The first cylinder return. 7. The second cylinder return. 8. Mould close.

Read More -

Plastic Electrical Junction Box Injection Mould

ABS Plastic Dustproof Waterproof Junction Box Universal Electrical Project Enclosure White 11.8" x 9.8" x 4.7"(300mmx250mmx120mm) The features of mold design are as below: 1. There are perforations on the 4 sides of the product; therefore, the cavity needs a small mold opening. 2. The 4 sides of the I-shaped drive the 4 sides of the slider to pull the core. 3. For the mold of the cover, in order to make the product look beautiful, the anti-adhesive is designed so that the product is firmly on the side of the fixed mold. 4. Simple mold design for easy maintain 5. On the side of the core, insert the insert inside and eject it with a thimble.

Read More