-

Rattan Chair Plastic Injection Mould

The plastic rattan chair biggest selling point is its appearance, which is exactly like a bamboo woven chair. However, the plastic rattan chair can improve the biggest weakness of bamboo chair: useful life. The bamboo woven chair is easy to break that has to be replaced within years, also the broken bamboo is likely to scratch customers. The size of plastic rattan chair is 63X53X53mm and the weight is 2.5kg. It is big but light, and is durable, strong, easy to clean, beautiful, and colorful.

Read More -

Children's stool plastic injection mould

There are more and more products specifically designed for children on the market. Because the needs of children's products are different from those of adults. Usually when designing children's products, safety and convenience of use are more considered.

Read More -

Two-in-one storage box chair

Almost all stackable chairs lose their reason for existence after stacking. Therefore, the design of this two-in-one storage box chair improves the usable value of the storage chair after stacking. The two-in-one storage box chair can be turned into a table or shelf after being stacked, but it can also be a good chair when you need it. This two-in-one storage box chair is versatile. It can also be fixed by stacking, and the chair has a high bearing capacity. This two-in-one storage box chair is available in two shapes, rectangular and square. They are stacked side by side with their uneven surfaces.

Read More -

Two-color handle stool plastic injection mold

The two-color handle stool is made of healthy PP material which is good in toughness. The stool structure is thickened, stable, and not easy to break. The two-color handle stool is durable and can bear up to 100 kgs. The reinforced rib design on the bottom of the two-color handle stool makes the stool stronger and more durable. The four stool feet have a non-slip pad design, which is non-slip and wear-resistant, which protects the floor and reduces wear and tear.

Read More -

Plastic stool injection mold

For the mold design, we use P20H as the main steel for this plastic stool injection mold. P20H is pre-hardened steel with HRC 30~33 which characteristics are good enough for making plastic stool injection mold. Besides, in the parts which are easy to rub, we use wear plates with HRC 45 above to ensure the production life of the plastic stool injection mold.

Read More -

Plastic chair injection mold

The advantages of plastic chairs are: 1. Plastic chairs are much more lightweight than other kinds of chairs. 2. Plastic chairs have rounded edges design which is safer than other kinds of chairs. 3. Plastic chairs are available in different color which has more choice than other kinds of chairs. 4. Plastic chairs are stackable which can help save the storage space.

Read More -

Thickening Gorgeous Diamond Low-Back Armchair Mold

What are the benefits of plastic furniture? 1. Plastic furniture is often more affordable than other options including wood and metal. 2. Plastic furniture is lightweight and easy to move around and rearrange. 3. Plastic furniture is mostly unbreakable; it won’t be damage with dropping. 4. Wooden furniture can develop cracks and require refinishing 5. Plastic furniture is available for variety of colors. 6. Plastic furniture is waterproof; it is the best option in rain. Plastic won’t be rust or cracked.

Read More -

Foldable stool plastic injection mold

The plastic foldable stool is composed of the stool surface and the stool legs. The connection between the stool surface and the stool legs is hinged. The lower part of the stool surface is concave, the lower part of the two stool legs is M-shaped or similar to M-shaped, and the concave part of the two stool legs and the middle part of the bottom surface of the stool surface are hinged by two connecting rods. The utility model has the advantages that the stool legs can be folded into the stool surface and viewed from the outside, which is only a stool surface and is very convenient to carry. In addition, the utility model has the advantages of reasonable structure, good mechanical properties and low price.

Read More -

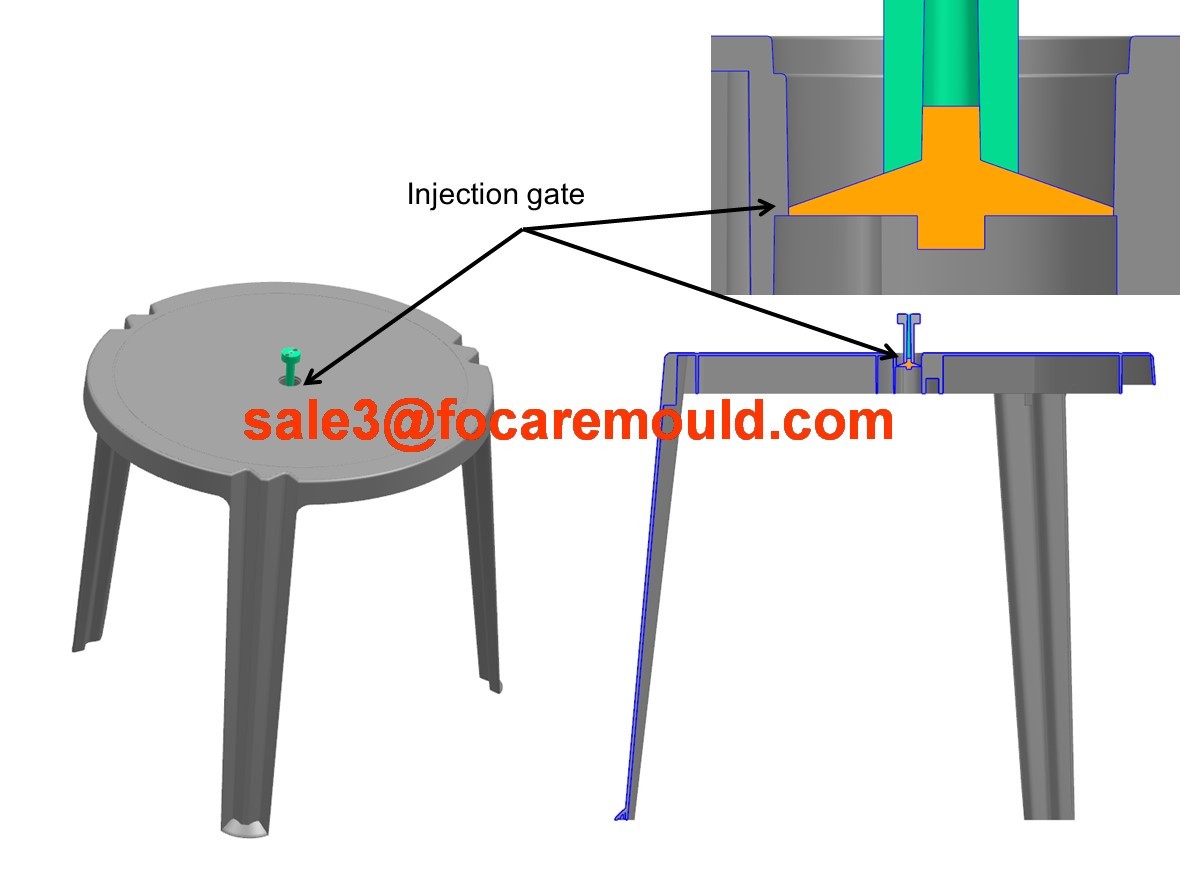

Plastic Garden Table Injection Mould

Traditional plastic injection tables have separated table legs. This means that the table top and the table legs are separate. In this way, we not only need to have extra mold for the table legs, the strength of the entire table will be weakened by the separate table legs. This plastic outdoor table is one-piece. The strength of the table is much stronger than separated tables. Besides, you don’t need to pay for extra leg mold.

Read More