-

Two-color square basin plastic injection mold

The two-color square basin is made of PP+TPE. The raw material PP is strong enough and let the basin has a very good support when it is filled with water. The raw material TPE is soft and let the two-color square basin be foldable. The two-color square basin is foldable and retractable freely. It is thin and light without taking up space. It is suitable for home and outdoor use. As the height of the two-color square basin is only 5.5 cm after folding, one can put it inside any size of luggage case. So, we don’t need to care about if the washbasin in the hotel is clean or not, just put a two-color square basin in the suitcase and we can easily use it in the hotel.

Read More -

Two-color foldable trash can plastic injection mold

To make a two-color foldable trash can that can fold and expand smoothly, the control of TPE part thickness is the key point. And to ensure the high efficiency of production, the cooling system needs especially design. Focare Mould, we are a team who specializes in making two-color plastic injection mold. We provide one-stop service, from product design to the mold test. Equipped with good CNC and injection machines, plus the technique and experience, we can help you to expand your business.

Read More -

Plastic storage drawers injection mold

Most of the plastic storage drawers are made of PP plastic. PP plastic, chemical name: polypropylene PP is a crystalline polymer. PP is the lightest in common plastics the density is only 0.91g / cm3 (smaller than water). Among general-purpose plastics, PP has the best heat resistance. Its heat distortion temperature is 80-100 °C and it can be boiled in boiling water. PP has good stress resistance, is not easy to have crack, and has a long service life. The overall performance of PP is better than PE. PP products are light weight, good toughness, and good chemical resistance.

Read More -

Plastic Baby Step Stool injection mold

Plastic Baby Step Stool provides just the right height, with Plastic Baby Step Stool; the baby can go to the toilet and wash his own hands. Moms can use Plastic Baby Step Stool to train their babies to learn about self-sanitation and good habits in life, so don't worry about it.

Read More -

Plastic photo frame injection mold

Focare Mould Co., Ltd. is a professional manufacturer of mould and plastic products. We have perfect ability of designing, developing, testing and making plastic injection moulds. Our professional technicians have many years of rich production experience. Since the establishment, we sincerely welcome customers from home and abroad to visit our factory for guidance and create a brilliant future with the principle of "professional quality, service value".

Read More -

Plastic bucket injection mold

Normally, in order to optimize your products, many people choice to use IML (in mold labeling) to have different kinds of products with only one plastic mold. But if you do not have the budget to purchase the IML system (normally one robot, one static generator, and labels), you can also consider to use texture on the surface of the plastic buckets. The texture can be the big logo of your company, the signs of your National culture or any drawings which can catch consumers’ eyes.

Read More -

Plastic foot bath bucket injection mold

With the plastic foot bath bucket, you do not need to spend extra money to do foot bath outside, we can enjoy foot bath at home every day. The design of raised dots on the bottom of the bucket allows us to do simple foot massage while soaking our feet. The wide mouth design makes it easy for us to soak our feet. Besides, the thickness of the plastic foot bath bucket is moderate, and the bucket will not be distorted due to the weight of water which will be happened only when the wall thickness is too thin.

Read More -

All-purpose bucket plastic injection mold

Normally the size of all-purpose buckets is from 25L to more than 210L. But we made this all-purpose bucket with the size no more than 0.5L. We can consider this all-purpose bucket as a toy for kids, company giveaway or storage bucket for desk for storing candies, paperclips, Elliot folders, etc. It can help you to organize your working desk.

Read More -

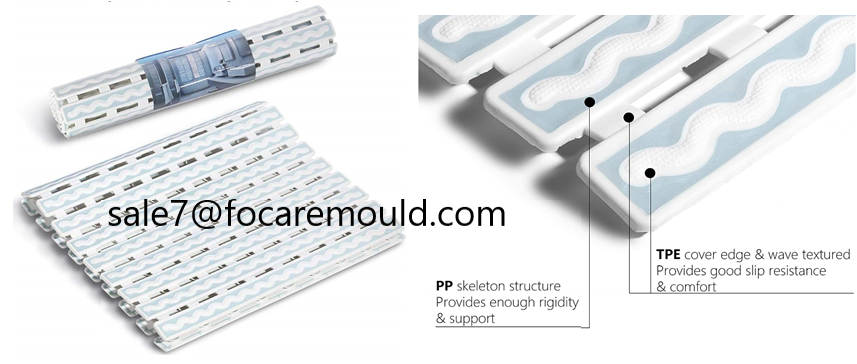

Two-color non-slip bath mat plastic injection mold

Here are some advantages of the two-color non-slip bath mat: 1. Special design: Being composed of a lot TPE material, two-color non-slip bath mat is non-slip on both sides. Besides, it also makes customer to have soft and comfortable using experience. The texture on surface even makes people have a foot massage when standing on it. 2. Hundreds of suction cups: The hundreds of TPE suction cups help the two-color non-slip bath mat to hold in place on smooth, clean surface. It is a great choice for home, gym, spa and more. 3. Drain holes: Feature with small holes, it allows water to pass through the two-color non-slip bath mat easily, that help to dry and avoid the moist growing underside. 4. Safe and antibacterial: Made by legal material, the two-color non-slip bath mat is antibacterial, mildew proof, non-toxic, BPA free, and Phthalate free. 5. Machine washable: Just throw the two-color non-slip bath mat into the washing machine to facilitate hassle-free maintenance and uphold its fresh appearance. 6. High quality: It is durable, with the proper preserve method; the two-color non-slip bath mat is available for long-time use. 7. Light weight: The two-color non-slip bath mat is light and easy to fold, easy to carry.

Read More