-

Pallet mold

Pallet mold is the core tool for producing durable plastic pallets, widely used in logistics, warehousing, and shipping. With strong structure, optimized cooling, and long mold life, it ensures high efficiency and consistent quality in large-scale production.

Read More -

Two Color Seal Ring Mold

Two Color 75mm Seal Ring Mold Mold Cavity: 8+8 Mold steel : European import 2316 Runner system: YUDO 16 tipsHR Two Color 110mm Seal Ring Mold Mold Cavity: 8+8 Mold steel : European import 2316 Runner system: YUDO 16 tips HR Two Color 160mm Seal Ring Mold Mold Cavity: 4+4 Mold steel : European import 2316 Runner system: YUDO 8 tips HR

Read More -

Two color screw driver handle mold

Two Color Screwdriver handle rotary core mold Product Material: PP+TPE Mould Cavity: 6+6 Hot Runner system: PP: 6 tips HR / TPE: 3-plate cold runner Mould Steel: Imported 2344 with HRC 45-48 Mold dimensions: 720 X 610 X 623 mm Mold size: 1994 kg Suggest machine: 280 tons rotary axis two color injection machine

Read More -

Industrial safety helmet mold

Industrial Safety helmet plastic injection mold Mould Cavity: 1 Hot Runner system: 1 tips HR Valve gate Mould Steel: P20H with HRC 28-30 Mold dimensions: 480 X 470 X 550 mm Mold size: 790 kg

Read More -

Two color SWR seal O-ring plastic injection mould

Focare Mould have not only good experience on making two-color O-ring molds with 4+4 cavities, 8+8 cavities or family molds, but also know-how on mold design and injection parameter adjustment which are key point to get high productivity moulds and low maintenance moulds.

Read More -

Two-Component Screwdriver Handle Plastic Injection Mould

Product Material:PP+TPE Mold Cavity:3+3 cavity Mold Main Material:H13 with hardness 45-48HRC Mold Injection System: 6tips hot runner system Mold Size:550X510X400 mm Suitable Machine: 280ton two component injection mold machine

Read More -

Nylon parts mould

Taizhou Huangyan Focare Mould Co., Ltd. has been committed to the professional development of injection mold since the establishment of the enterprise. Now it has strong R & D ability, complete technical team and perfect production process. We can quickly provide customers with superior mold design solutions. We can design and manufacture various injection molds according to customers' requirements. At the same time, we can also use advanced design software and measuring equipment to design and manufacture molds according to the drawings, samples and specifications provided by customers, and win the unanimous recognition of customers at home and abroad!

Read More -

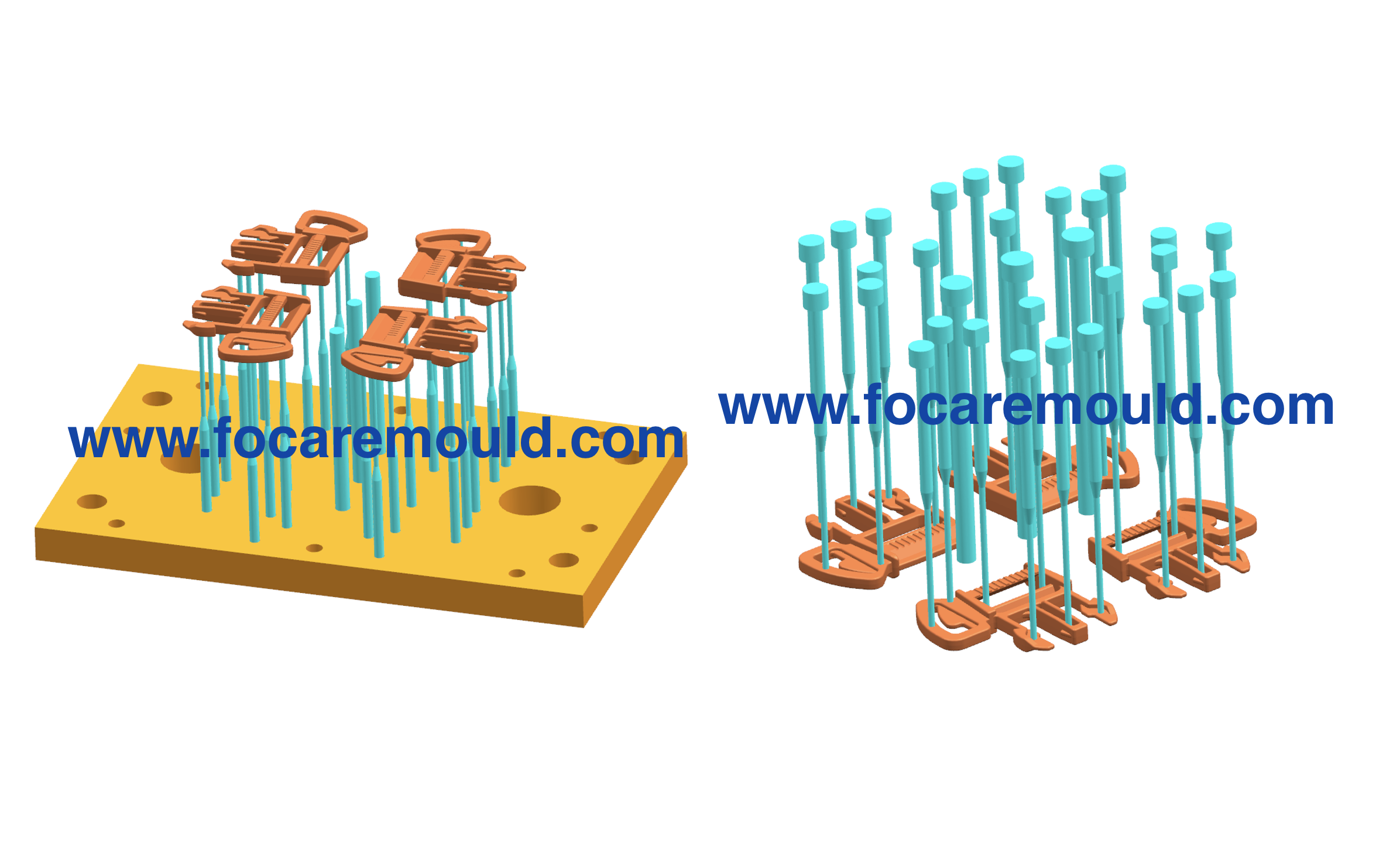

Plastic buckles injection mold

Plastic buckle, this type of buckle is suitable for adjusting the length of luggage leather. It is also called adjusting buckle, opposite buckle and side opening buckle. According to different raw materials, it can be divided into plastic buckle (POM, PP, PA material) and plastic buckle (aluminum alloy, semi aluminum alloy) for hardware fittings. It can be divided into single adjustment plug-in, double adjustment plug-in and non-adjustment plug-in according to whether to adjust or not. According to different uses, it can be divided into baby carriage plug-in, pet plug-in, outdoor safety plug-in and luggage plug-in.

Read More -

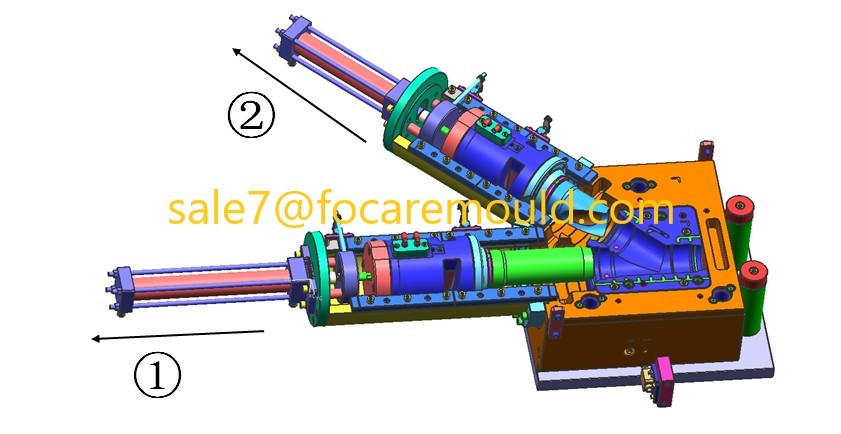

Plastic Pipe Fitting Plastic Injection Mould

To make sure the pipe fitting plastic injection mould has the highest efficiency, the mould will need careful design and calculation for gears. The cooling channels also should be well-designed to reduce cycle time and improve productivity. Below are the movements of D125 Y Pipe Fitting Mould: 1. Mould open. 2. The second cylinder move. 3. The first cylinder move. 4. Ejector bars drive the ejector plate and eject product. 5. Ejector pins return due to the springs. 6. The first cylinder return. 7. The second cylinder return. 8. Mould close.

Read More