- Home

- >

- Products

- >

- Industrial Parts Mold

- >

- Seal Ring / Pipe Fitting Mold

- >

- Plastic Pipe Fitting Plastic Injection Mould

Plastic Pipe Fitting Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

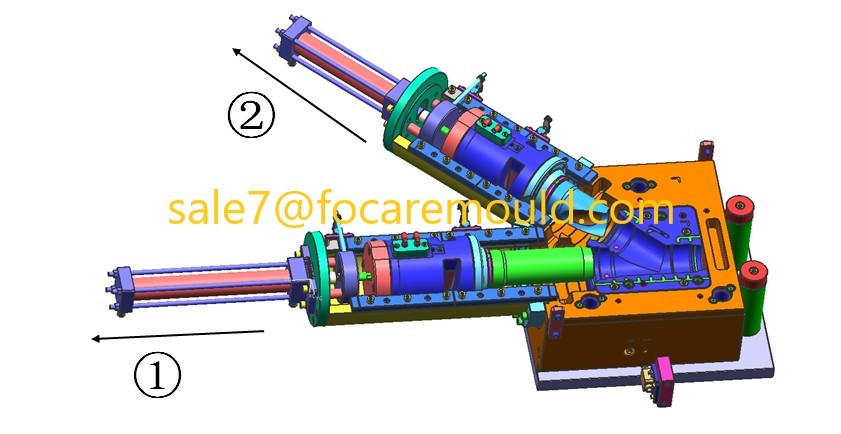

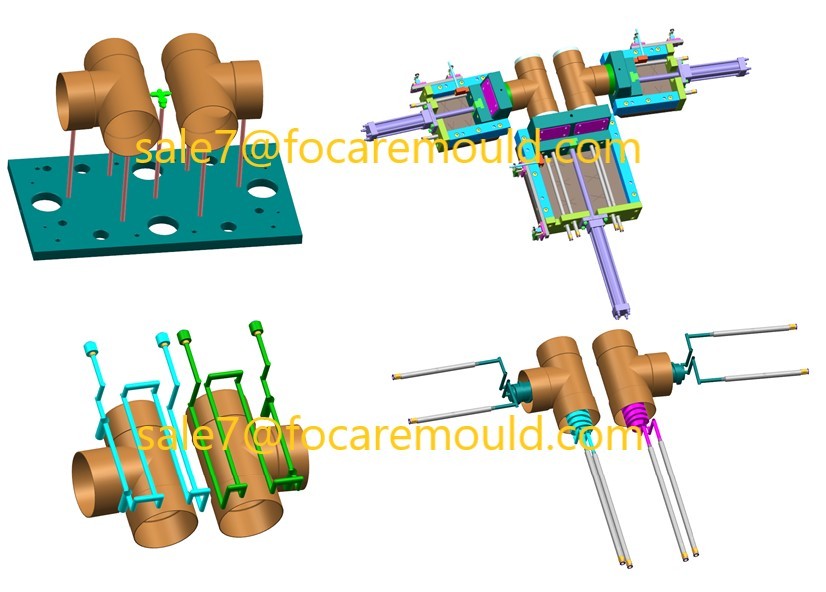

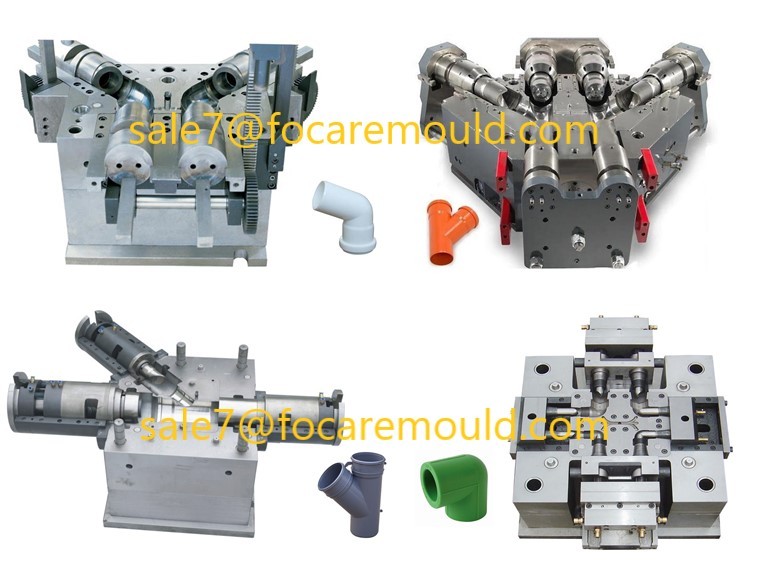

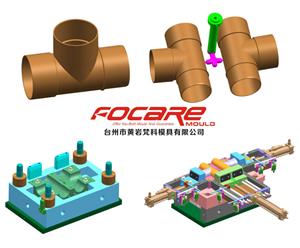

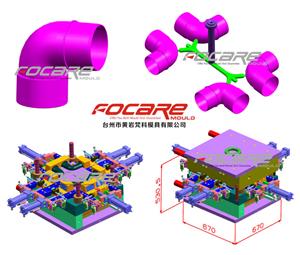

To make sure the pipe fitting plastic injection mould has the highest efficiency, the mould will need careful design and calculation for gears. The cooling channels also should be well-designed to reduce cycle time and improve productivity.

Below are the movements of D125 Y Pipe Fitting Mould:

1. Mould open.

2. The second cylinder move.

3. The first cylinder move.

4. Ejector bars drive the ejector plate and eject product.

5. Ejector pins return due to the springs.

6. The first cylinder return.

7. The second cylinder return.

8. Mould close.

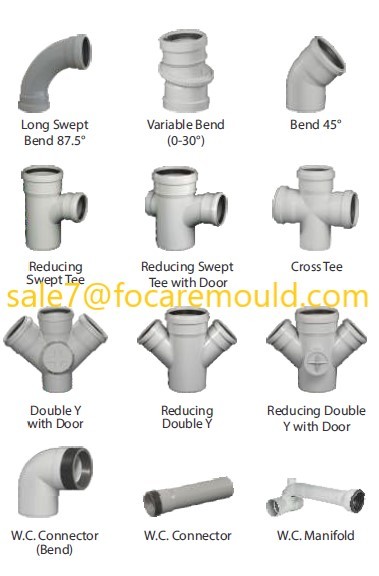

Pipe fittings are widely used for ventilation, domestic water supply and water drainage. They have the functions of connection, control, change direction, diversion, sealing, support and so on. People adopted metal ones at first, but due to it being heavy and likely to get rust, it has been quickly replaced by plastic one, which is light, waterproof and durable.

uPVC pipes were used to replace corroded metal pipes and thus bring fresh drinking water to a growing rural and later urban population. uPVC pipes are certified safe for drinking water per NSF Standard 61 and used extensively for water distribution and transmission pipelines throughout North America and around the world. uPVC is allowed for waste lines in homes and is the most often used pipe for sanitary sewers.

CPVC is resistant to many acids, bases, salts, paraffinic hydrocarbons, halogens and alcohols. It is not resistant to solvents, aromatics and some chlorinated hydrocarbons. It can carry higher temperature liquids than uPVC with a max operating temperature reaching 200 °F (93.3 °C). Due to its greater temperature threshold and chemical resistance, CPVC is one of the main recommended material choices in residential, commercial, and industrial water and liquid transport.

PP is suitable for use with foodstuffs, potable and ultra-pure waters, as well as within the pharmaceutical and chemical industries. Due to the high impact resistance combined with good stiffness and high chemical resistance makes this material suitable for sewer applications. A good performance at operating temperature range from up to 60 °C (140 °F) (continuous) makes this material suitable for in-house discharge systems for soil & waste. A special PP grade with high temperature behavior up to 90 °C (194 °F) (short-term) makes that material a good choice for in-house warm water supply

PE has been successfully used for the safe conveyance of potable and waste water, hazardous waste, and compressed gases for many years. PE is lightweight, flexible and easy to weld. Its smooth interior finish ensures good flow characteristics. Continuous development of the material has enhanced its performance, leading to rapidly increasing usage by major water and gas utility companies throughout the world.

To make sure the pipe fitting plastic injection mould has the highest efficiency, the mould will need careful design and calculation for gears. The cooling channels also should be well-designed to reduce cycle time and improve productivity.

Below are the movements of D125 Y Pipe Fitting Mould:

1. Mould open.

2. The second cylinder move.

3. The first cylinder move.

4. Ejector bars drive the ejector plate and eject product.

5. Ejector pins return due to the springs.

6. The first cylinder return.

7. The second cylinder return.

8. Mould close.

The sequence of movements is very important, or the product may have flash and the ejector pins may be broken.

Focare Mould, we have made all kinds of pipe fittings and two-color o-ring for assembly. Below is the introduction of two-color o-ring, welcome to consult and contact us if there is any question.