- Home

- >

- Products

- >

- Multi-Color Mold

- >

- Two color bike seat mold

Two color bike seat mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

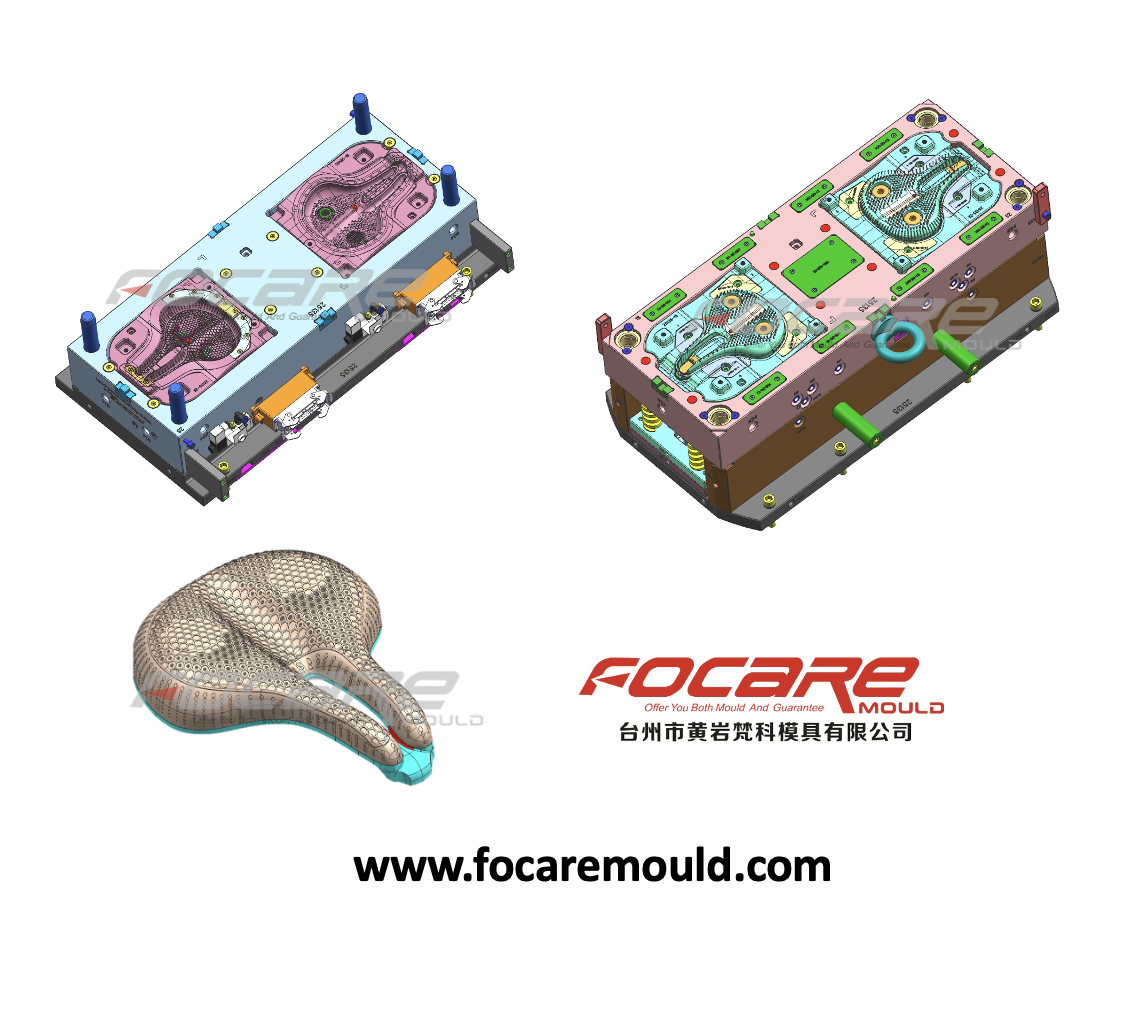

Two-Color Bike Seat Mold

Mold Cavity: 1+1

Mold steel : 718H

Runner system: 2 tips vavle gates

Detail information of Two-Color Bike Seat Mold

Two-Color Bike Seat Mold

Mold Cavity: 1+1

Mold steel : 718H

Runner system: 2 tips vavle gates

In today’s competitive bicycle market, product appearance and comfort are just as important as performance. One of the most effective ways to enhance both is through two color injection molding, especially for components like bike seats. A well-designed two color bike seat mold allows manufacturers to combine different materials and colors in a single molding process, creating seats that are visually appealing, durable, and comfortable.

What Is a Two Color Bike Seat Mold?

A two color bike seat mold (also known as a 2K mold or double-shot mold) is designed to inject two different plastic materials or colors into one product during a single molding cycle. This technology is commonly used for:

Soft + hard material combinations

Anti-slip surfaces

Ergonomic comfort layers

Stylish color contrast designs

For bike seats, this means better grip, improved comfort, and a premium look without extra assembly steps.

Why Use Two Color Molding for Bike Seats?

Two color molding offers several advantages:

Enhanced Comfort

Soft TPE or TPU layers can be molded directly onto a rigid plastic base, improving rider comfort.

Stronger Bonding

Since both materials are molded together, the bond is more durable than glued or assembled parts.

Better Appearance

Color contrast creates a high-end, sporty look that attracts consumers.

Higher Production Efficiency

One mold, one cycle, one finished product — saving time and labor.

Conclusion

A high-quality two color bike seat mold can significantly improve product comfort, appearance, and market competitiveness. By working with a professional China mold maker like Focare Mould, brands can achieve efficient production, consistent quality, and eye-catching designs.

If you're looking for a trusted China mold making factory to support your two color bike seat project, Focare Mould is ready to help you bring your ideas to life.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services