- Home

- >

- Products

- >

- Industrial Parts Mold

- >

- Pallet mold

Pallet mold

Brand :Focare Mould

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

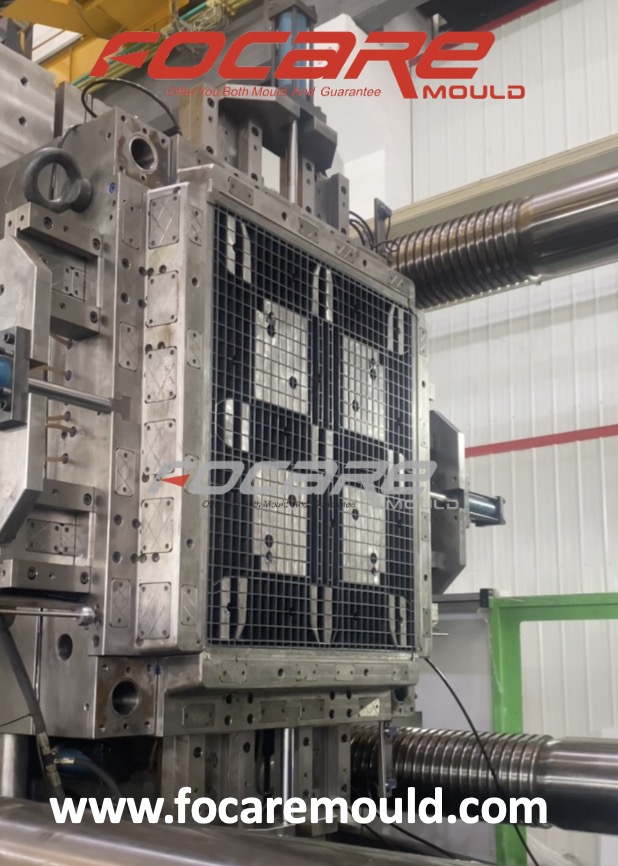

Pallet mold is the core tool for producing durable plastic pallets, widely used in logistics, warehousing, and shipping. With strong structure, optimized cooling, and long mold life, it ensures high efficiency and consistent quality in large-scale production.

Detail information of Pallet mold

Plastic pallets have become an essential part of modern logistics and warehousing, replacing traditional wooden pallets with higher durability, hygiene, and reusability. To meet the growing demand, a reliable pallet mold is the key to producing high-quality plastic pallets.

Key Advantages of Pallet Molds

Strong structure: Designed to handle heavy loads and repeated forklift operations.

Durable materials: Mold base and core/cavity made from premium steel such as 718H, H13, or S136 to ensure long lifespan.

Optimized cooling system: Reduces cycle time while maintaining stable quality.

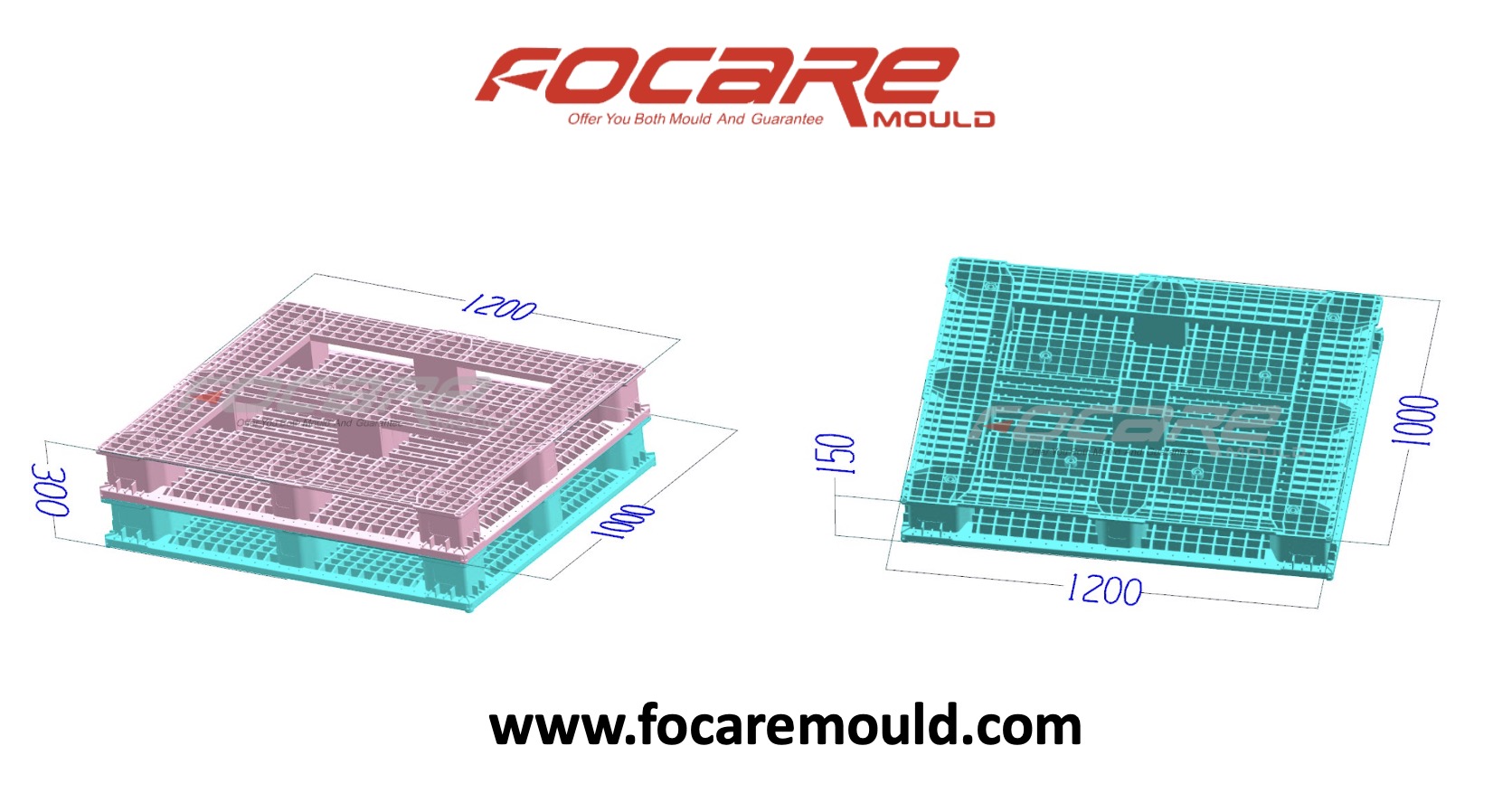

Flexible design options: 2-way / 4-way entry, rackable or nestable types, anti-slip surface, and steel reinforcement available.

Applications

Logistics & Warehousing: Standard size pallets (1200×1000 mm, 1200×800 mm, etc.) for heavy-duty storage.

Food & Beverage: Hygienic and washable pallets, safe for transporting food-related goods.

Export & Shipping: ISPM 15 exempt, eliminating fumigation requirements of wooden pallets.

Why Choose Focare Mould?

At Focare Mould, we specialize in designing and manufacturing large pallet molds that meet global standards. With years of expertise, we deliver molds that ensure:

High efficiency in mass production

Strong and durable pallet performance

Cost savings and eco-friendly benefits

Focare Mould is a trusted China two color mold maker, based in Huangyan. Contact us to develop your custom two-color mold solution.

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services