- Home

- >

- Products

- >

- Plastic Chair & Table Mold

- >

- Multi Purpose Plastic Stool Injection Mould

Multi Purpose Plastic Stool Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

The important points which we care about when we make chair molds:

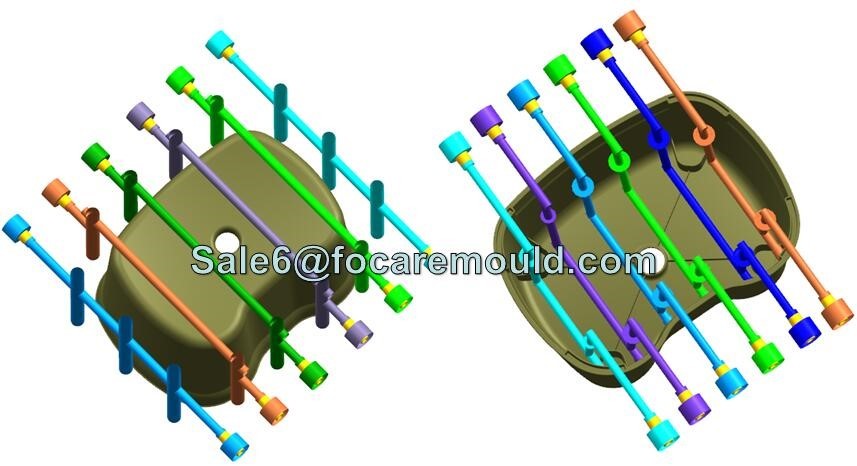

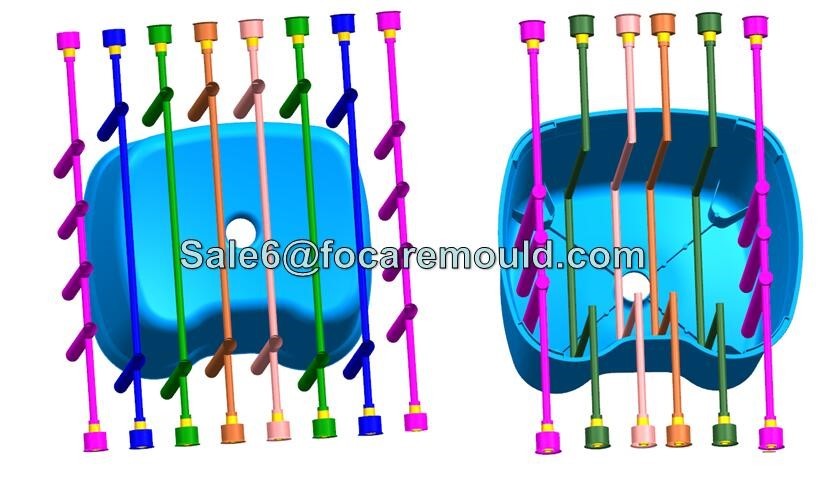

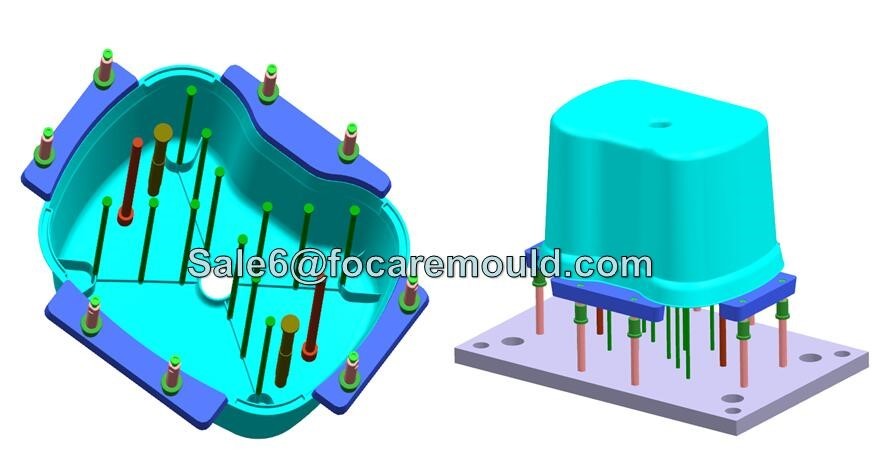

1) We add as many cooling system as possible including the chair surface to ensure outstanding cooling performance.

2) We add wear plates with 45HRC above to guarantee the chair molds’ life.

3) We use steel with 30-33HRC.

4) We use high speed CNC machine to reach 0.02 mm precision.

The important points which we care about when we make chair molds:

1) We add as many cooling system as possible including the chair surface to ensure outstanding cooling performance.

2) We add wear plates with HRC 45 above to guarantee the chair molds’ life.

3) We use steel with HRC 30~33.

4) We use high speed CNC machine to reach 0.02 mm precision.

Plastic children's chairs are compared to traditional wooden chairs:

1. Beautiful appearance, sturdy and durable

2. There are many style changes, suitable for all occasions

3. Waterproof, easy to clean

4. Easy to carry and convenient to use

5. Long service life, low maintenance costs and low plastic manufacturing costs

Common chair materials are not only plastic or wooden, but also stainless steel, but stainless steel is easy to rust and difficult to repair. Wooden chairs are heavy and not waterproof, and are not convenient to carry. Most plastic chairs are light and resistant to rust and water, and are easy to carry and easy to clean. I believe that plastic chairs have the greatest advantage in the world market.

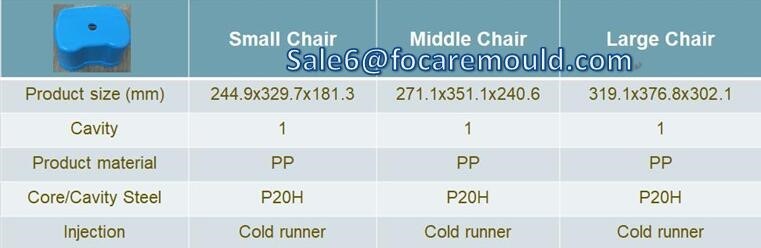

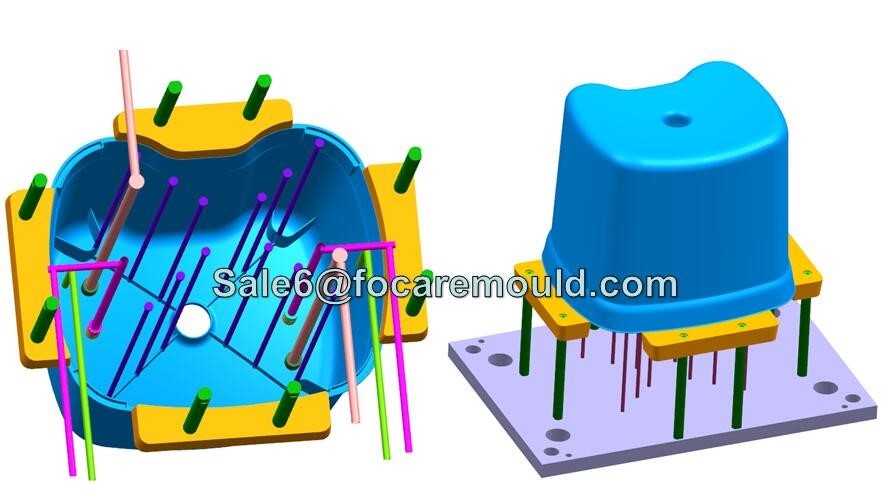

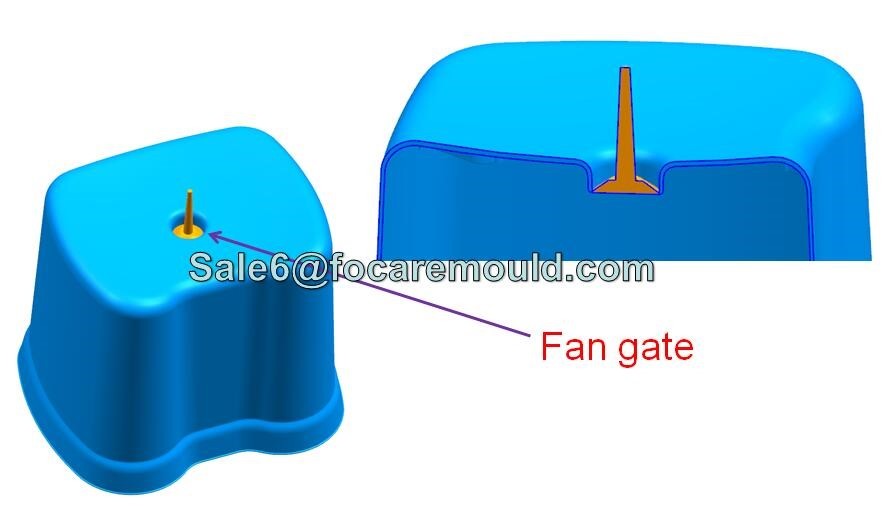

This chair of child the mold steel use P20H, which is pre-hardened steel. Because the heat treatment has been carried out first, the steel can be processed immediately as soon as it arrives. P20H has relatively uniform hardness, good processing and polishing performance, is more suitable for EDM, and has the advantages of good dimensional stability, and the injection method adopts the cold runner fan gate method for injection. The ejector product is using air valve, gas pin, ejector pin and ejector block.

Focare Mould has experiences in gas assistant chair molds, rattan chair molds, arm and armless chair molds, foldable chair molds, baby chair molds, etc. Please contact with us if you need more information.