- Home

- >

- Products

- >

- Multi-Color Mold

- >

- Double Color Wheel of Toy Car Plastic Injection Mould

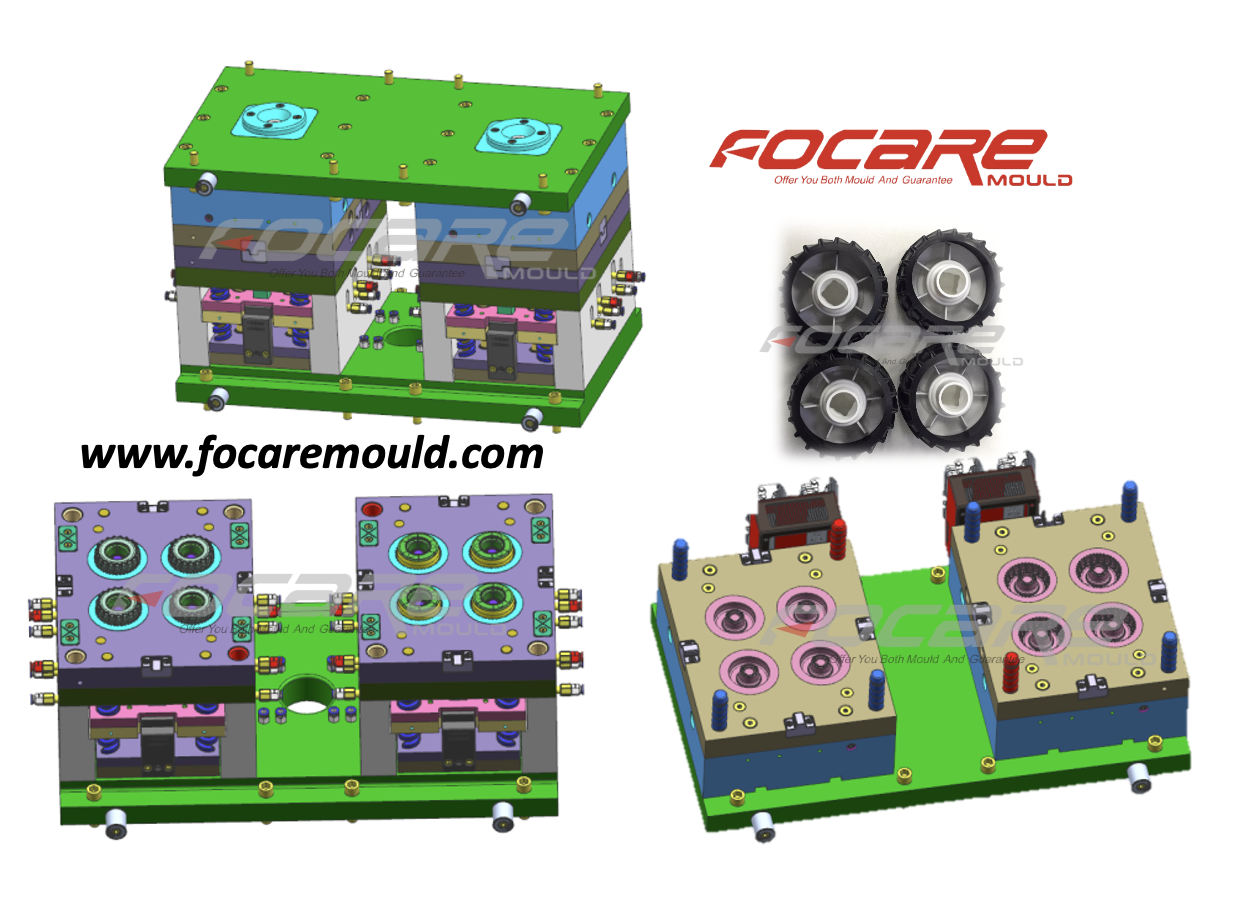

Double Color Wheel of Toy Car Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :90 days

Supply capacity :300 molds per year

Product Material: PP+TPE

Mould Cavity: (2+2)+(2+2)

Hot Runner system: Hot runner

Mould Steel: S136

Mold dimensions: 810 X 470 X 501mm

Mold size: 929 kg

Suggested machine: 280 tons two color rotary table machine

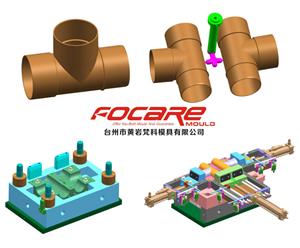

Detail information of Double Color Wheel of Toy Car plastic injection mold

Product Material: PP+TPE

Mould Cavity: (2+2)+(2+2)

Hot Runner system: Hot runner

Mould Steel: S136

Mold dimensions: 810 X 470 X 501mm

Mold size: 929 kg

Suggested machine: 280 tons two color rotary table machine

In the past, the materials of toy car wheels were mostly rubber, which had excellent tensile and tear strength, good resistance.

However, rubber needs to be vulcanized, processing cycle time is too long, and waste materials are difficult to be recycled.

In recent years, TPE began to be widely used in all kinds of toy car wheels, most of the toy car wheels do not have high requirements for load-bearing.

Compared with rubber, TPE also has excellent wear resistance, tensile strength, cushioning and shock absorption, and has thermal plasticity. It can be directly injection mold without vulcanization, greatly reducing the production cycle.

Moreover, TPE is environmentally friendly and non-toxic, which is more recognized by toy end consumers.

This double color wheel is made by PP of wheel frame and TPE of outer soft part.

PP is rigid material which is good enough to support the weight of toy car.

The weight of PP is lighter than steel frame, it is suitable for making toys.

TPE could be produced by traditional injection molding machine, meanwhile, PP and TPE could be injected and plasticized together well, not easy to be separated by force.

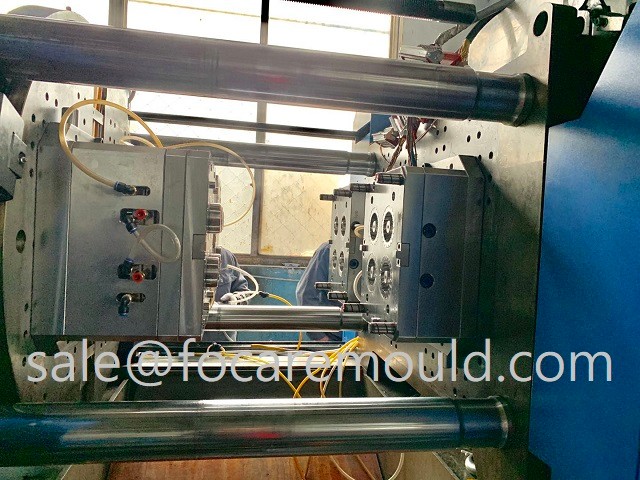

The mold is designed for rotating double color injection moulding process.

The rotary double color injection mold is composed with two molds, the first mold is for making PP part, second mold for TPE part after PP part being injected and rotated to second position.

Focare Mould is China professional multi shot mold manufacturer,china mold maker, multi shot injection molding expert.

We can offer you high quality bi material double component two color 2k wheel of toy car plastic injection mold.

If you want to make a high quality bi material double component two color 2k wheel of toy car plastic injection mold, welcome to contact us.

Our professional team will alway give you more information about two color 2k wheel of toy car plastic injection mold .

Why choosing Focare Mould as your work partner?

1

Professional

One step and turnkey solution from part & mold design,mold tooling, making and injection molding to final delivery

2

Experienced

Advanced tooling equipment with rich experience in plastic mold & multi shot mold manufacturing

3

Reliable

Professional service team provides injection molding technical support and quick after sale mold services