- Home

- >

- News

- >

- Company News

- >

- Double Ejecting System

Double Ejecting System

Generally speaking, the ejection action of the finished product from the mold is completed at one time, whether using single or multi-component ejection mechanism. However, due to the special shape of the finished product, or the requirement of mass production, if the finished product is still in the mold cavity after one ejection, or when it can not automatically fall off, it needs to add another ejection action. Such ejection action design is called 2 Times ejection. 2 Times ejection can make ejection flow smoothly. For some products requiring larger ejection travel, the use of 2 Times ejection can reduce the force exerted by the ejection pin and avoid the defects caused by the ejection pin.

2 Times ejection mechanism, in short, can be divided into the following three categories:.

(1) 2 Times ejection mechanism of single ejector plate combination

(2) 2 Times ejection mechanism of double ejector plate combination

(3) Pneumatic/hydraulic secondary ejection mechanism

Double ejection mechanism of single ejector plate combination

The so-called single ejector plate combination is a common single set of ejector plate combination (upper and lower ejector plates are each one). Because there is only one set of ejector plate combination, the ejector ejection action only provides the traditional one ejection; the other ejection must be carried out with other die mechanism design (such as spring).

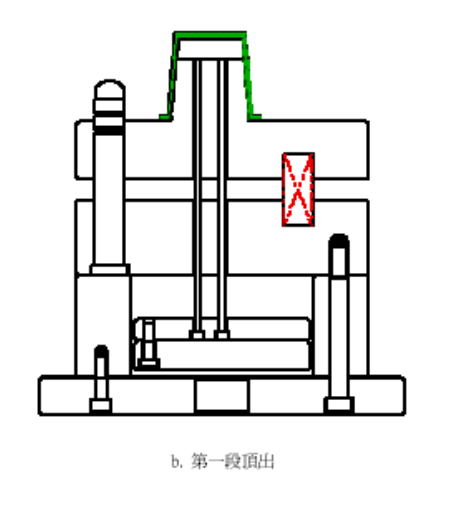

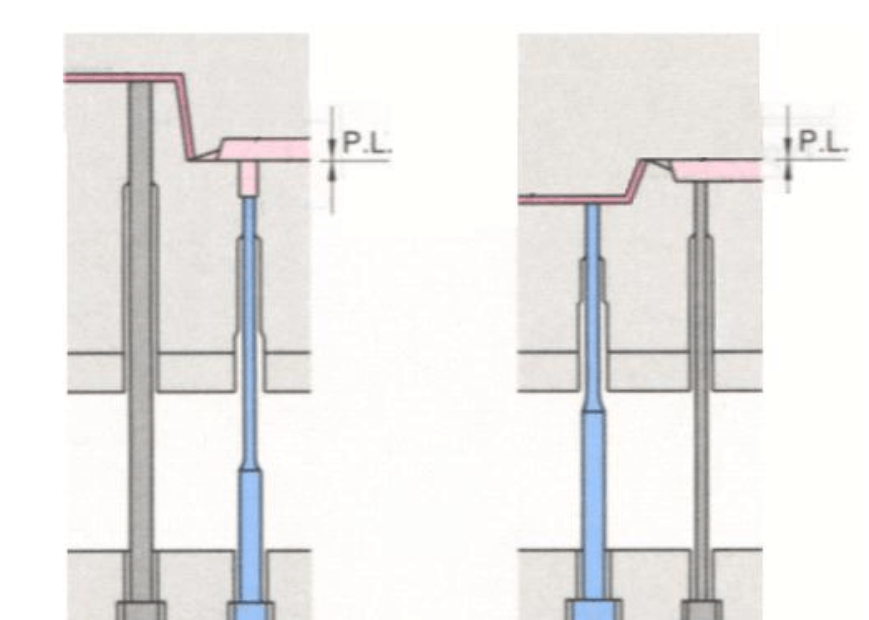

In the second stage, the ejection is operated by the ejector plate, and the ejector pin is used to eject the product from the die hole.

2 Times ejection with spring is the simplest method in die structure, and there are few parts requiring extra processing. However, the weakness of spring (elastic fatigue) is also the weakness of this ejection method. Whether the spring can move smoothly and check the ejection travel of the first ejection are the safety measures to avoid the failure of the die mechanism.

There are several kinds of deformations in the pop-up 2 Times ejection of male and female formwork.

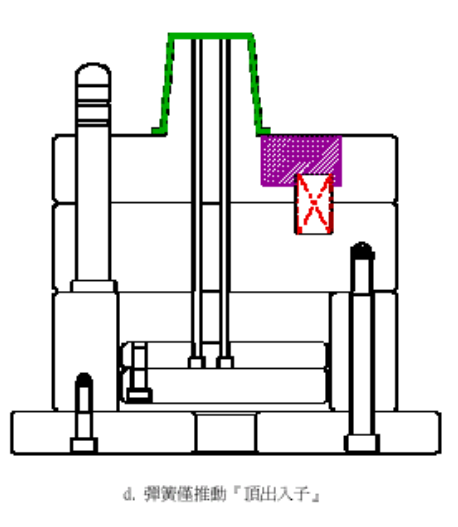

1. Replace the spring-driven template with the spring-driven "top-in-out" template.

As shown in the figure above, the whole template is driven by a spring. In practical application, according to the shape of the product, it can be changed to push the jack in and out. For example, the following figure can reduce the weight to be overcome each time the spring is pushed, and increase the life of the spring.

2. If the first jacking stroke does not need to be very long, it is also a feasible method to replace the spring with superior glue. Youli rubber is a kind of foamed material made of artificial rubber, its compression ratio is not high, about 1/3; unlike coil springs, the compression ratio can reach 1/2. The hardness of the spring is similar to that of the pneumatic spring. The harder the pressure is, the harder the spring will be, but the harder it will be in a shorter journey. Its fatigue strength is not as good as that of coil spring, but it can be maintained for a long time with moderate lubrication. The trouble with Ultra Glue is that it is very sensitive to temperature. It hardens at low temperatures and softens at high temperatures. Users must pay special attention to their service life in use, and remember to check and replace the defective materials when maintaining the mold.

Open-type 2 Times ejection of male and female formwork

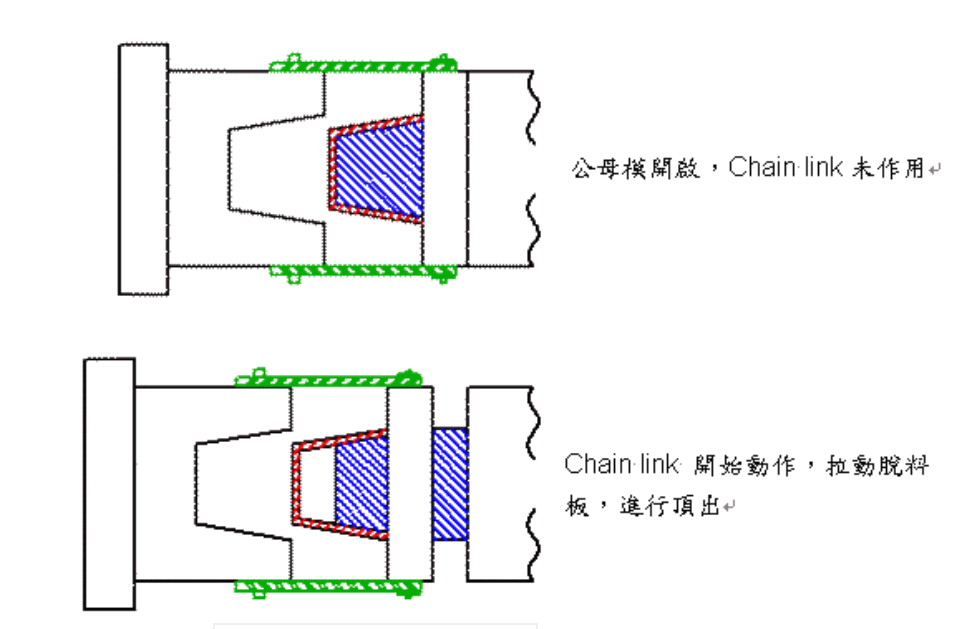

lthough the spring can be used to eject the stripper after opening the die, the force of the spring is not enough for the large die base. Therefore, there are other agencies to deal with such problems. This kind of organization, which we call Tension Links, is shown below.

Generally speaking, in order to avoid the operation of the mechanism, there will be some additional mechanisms to ensure the smooth operation of the original mechanism design. The organization that cooperates with chain link is the chain.

2 Times ejection of pin-plate combination mechanism

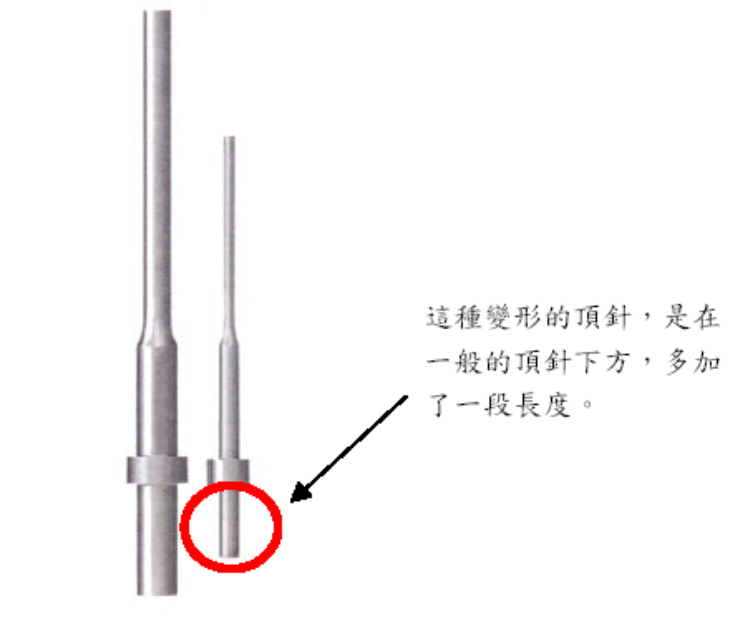

2 Times ejection can also be accomplished by changing the ejector pin.

So far as the ejector pin adopts two-section ejector pin, it only increases the strength of the ejector pin and avoids the deflection when the ejector pin is ejected. A kind of using this ejector to complete two-stage ejection is the simplest in the die structure, as long as the ejector plate on the hands and feet on the line. A kind of the example given here is to use this mechanism to cut off the latent gate.

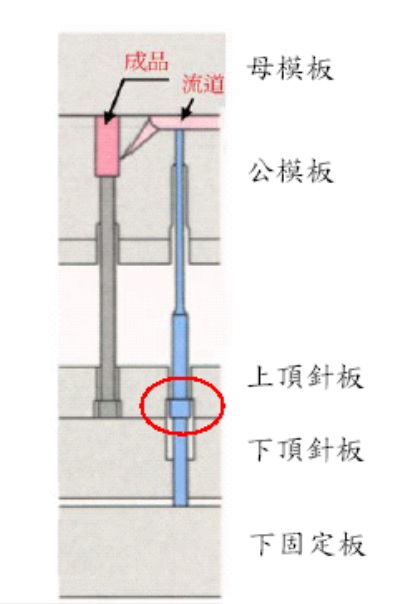

When ejecting, the left ejector will move first, and the right ejector will not start until the lower fixing plate reaches the ejector pin circled by red lines below the right ejector pin. A kind of this kind of secondary ejection structure can avoid the damage of the finished product when the latent gate is ejected and the gate is pulled away from the finished product. A kind of the side gate can also be ejected in a similar way to avoid damaging the finished product at the gate position.

Of course, this ejection is not only used near the gate. Since the starting position of the second ejection stroke can be achieved only by changing the columnar length below the ejector pin, and the cost of die making is relatively low, this ejection method is also suitable for the deep box ejection mentioned earlier.

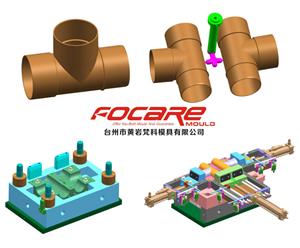

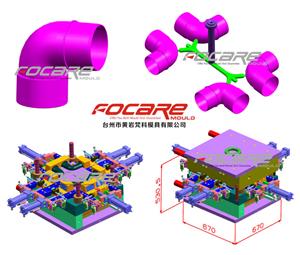

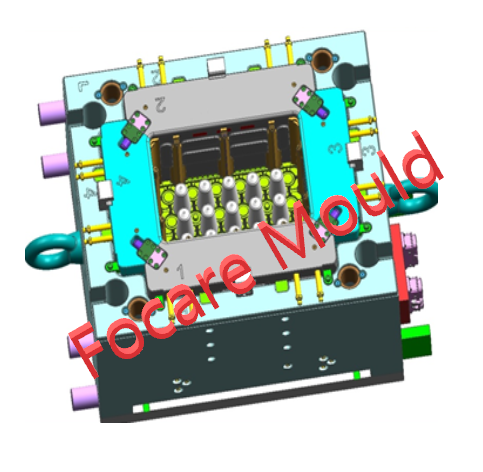

As per carte mold structure design will also use this kind 2 Times ejection.

This is the 2 Times mechanism Design. After the first time slider eject, the slanted roof is fixed. The stripper plate continues to eject

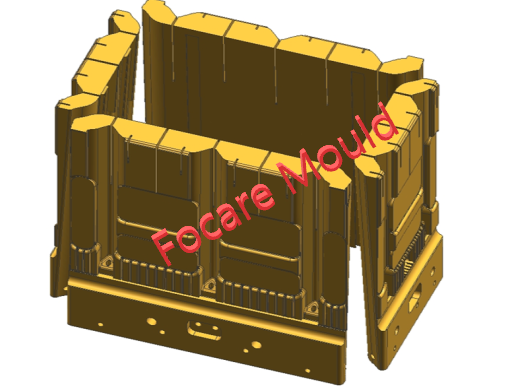

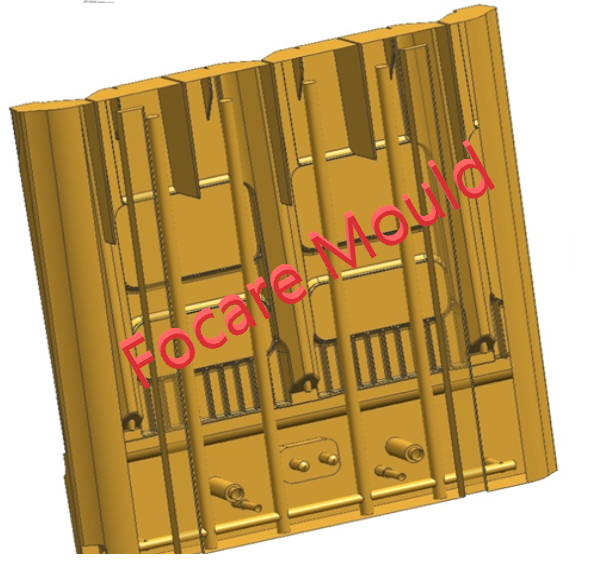

This is a beer box

The main technical point is :

(1) Cavity four sliders

(2) Four inclined tops of the core (the oblique top waterway needs to be made straight through, and the U-shaped waterway cooling effect is not good)

(3) When the product is ejected, it is necessary to use a cylinder. The cylinder pushes the stripper out, drives the core to slant the top, and finally pushes the product out of the core.