PP Injection Molding Guide | China Mold Maker | Focare Mould

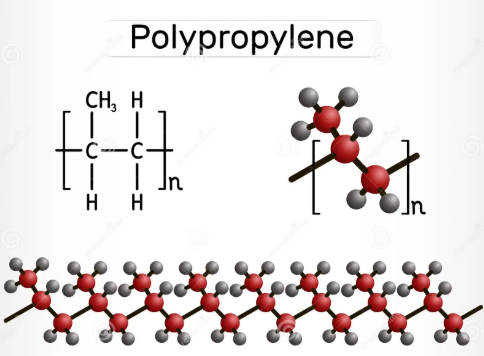

What is Polypropylene (PP)?

Polypropylene (PP) is one of the most widely used thermoplastics in plastic injection molding. It is known for its lightweight, chemical resistance, toughness, and recyclability. PP is FDA/EU approved for direct food contact, making it a popular choice in food packaging, household products, automotive, and medical industries.

At Focare Mould, as a leading China mold maker, we specialize in designing high-precision PP molds to meet global clients’ needs for efficiency, durability, and cost-effective production.

Key Properties of PP for Injection Molding

Low density & lightweight → reduces product weight and shipping costs.

Excellent chemical resistance → resists acids, bases, detergents, and solvents.

Good fatigue resistance → suitable for “living hinges” like flip-top lids.

Safe for food contact → widely used in food containers, lids, and packaging.

Recyclable → eco-friendly choice supporting sustainable production.

Common Applications of PP Injection Molding

1. Food Packaging & Household Products

Food containers, lunch boxes, storage boxes

Takeaway cups, lids, disposable bowls

Microwave-safe products

2. Consumer Goods

Toothbrush handles (often 2K injection with TPE for grip)

Toys, stationery, luggage parts

Home appliances and storage solutions

3. Automotive Industry

Interior trims, dashboards, door panels

Battery cases, ventilation components

Bumpers and lightweight structural parts

4.Medical & Healthcare

Syringes, medicine bottles, lab consumables

Disposable healthcare containers

5. Industrial Products

Pallets, crates, pipes, fittings

Packaging films and straps

PP Injection Molding Process Parameters

Melt temperature: 200 – 280°C

Mold temperature: 20 – 80°C (higher for improved surface finish)

Injection pressure: 700 – 1200 bar

Shrinkage rate: 1.0 – 2.5% (must be considered in mold design)

Drying: Generally not required, but recommended if stored in humid environments

At Focare Mould, our engineers carefully optimize parameters to achieve shorter cycle time, dimensional stability, and reduced warpage.

Design Considerations for PP Molds

Wall thickness: Uniform thickness (typically 0.8 – 3.0 mm) to avoid sink marks.

Living hinges: PP is ideal for integrated hinges, requiring precise mold design.

Ribs & gussets: To enhance strength while minimizing material use.

Cooling system: Optimized baffle or BeCu inserts to reduce cycle time.

Gating: Hot runner system recommended for high-volume PP parts.

Conclusion

Polypropylene (PP) injection molding continues to dominate industries from food packaging to automotive because of its balance of cost, durability, and safety. With the right PP mold design, manufacturers can achieve fast cycles, stable quality, and long mold life.

At Focare Mould, we are proud to be a trusted China PP mold maker with proven experience in delivering molds that help our clients stay competitive in the global market.