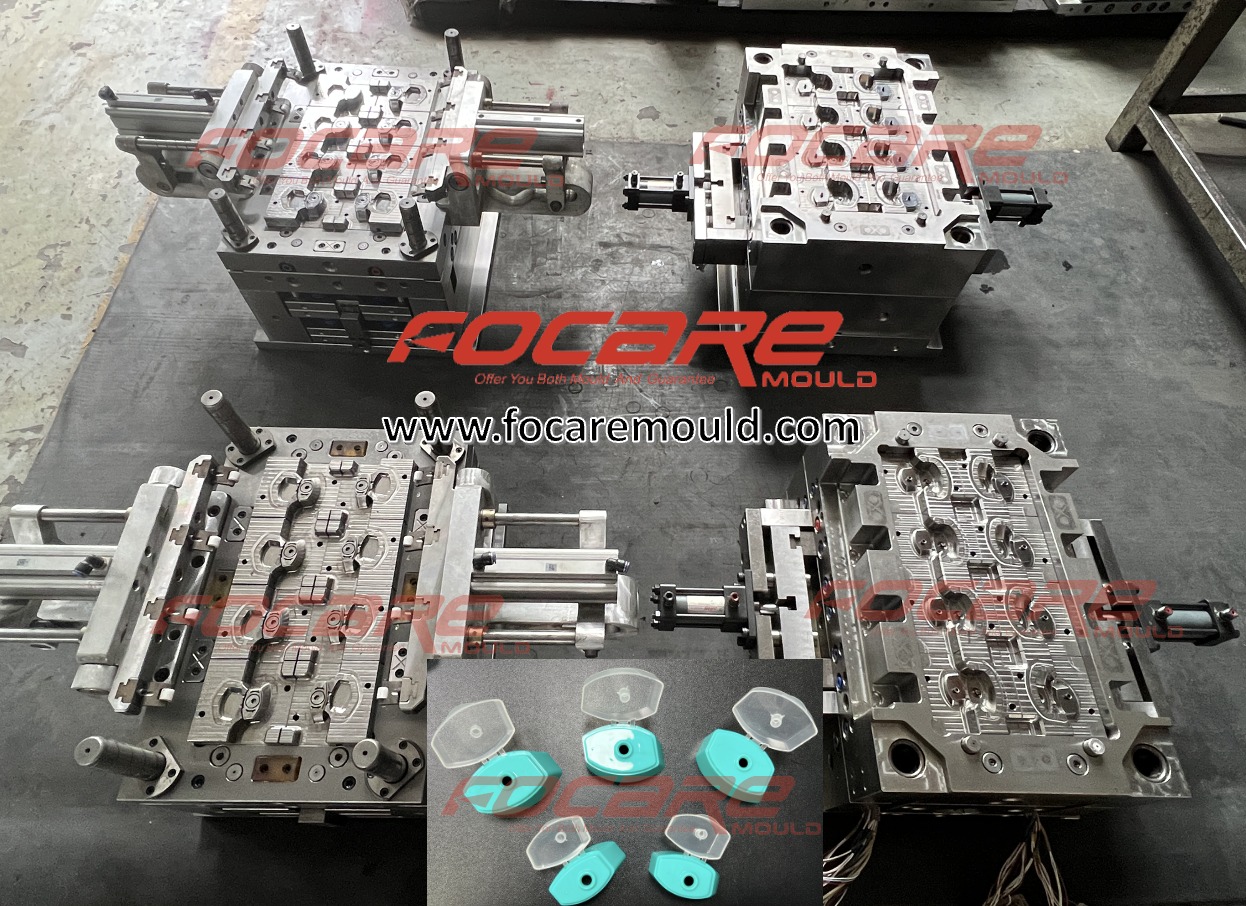

Case Study: Two Color Flip Top Cap Mold

Case Study: Two Color Flip Top Cap Mold

Customer Requirement

A leading packaging company required a two color flip top cap mold for their cosmetic and household containers. They wanted a design that offered:

Smooth and durable flip top opening and closing.

A stylish two color injection molding finish for better branding.

Technical Challenges

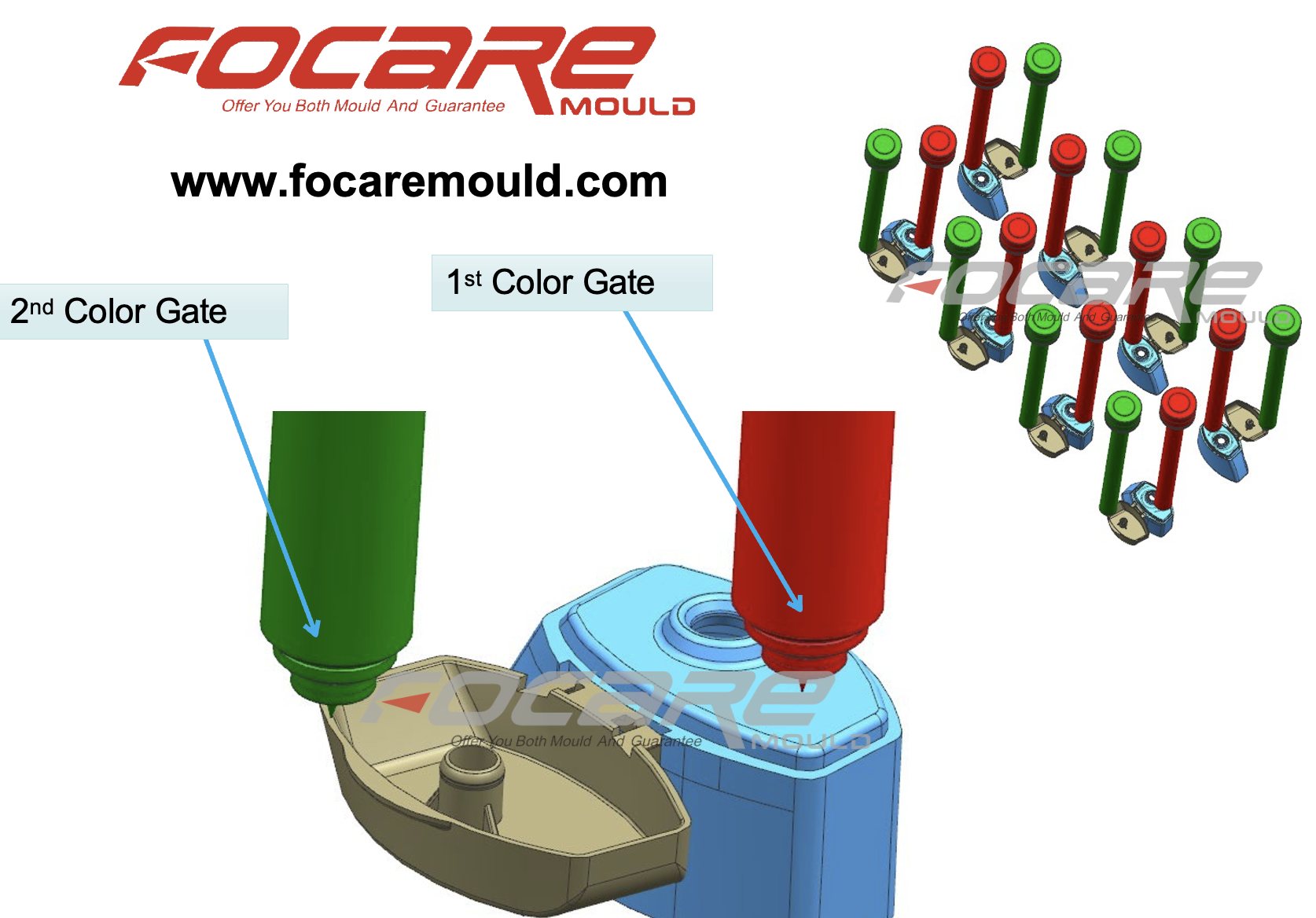

Maintaining perfect alignment of two different materials in a 2K mold, avoiding leakage, weak bonding, or defects.

Guaranteeing high production efficiency and long mold life for continuous mass production.

Focare Solution

Utilized advanced 2K rotary platen technology to ensure accurate positioning for the two color molding process.

Applied S136 hardened steel and a hot runner system, extending mold durability and delivering a premium surface finish.

Conducted Moldflow analysis to validate filling, cooling, and cycle time optimization before mold manufacturing.

Result

The client launched a successful two color flip top cap series, widely applied in cosmetic packaging and household products.

Production cycle time improved by 30%, while assembly labor cost was reduced by 40%.

The client was satisfied with the quality and efficiency, leading to repeat orders for more two color injection molds.

Conclusion

Focare Mould is a trusted China two color mold maker, based in Huangyan mould factory zone, specializing in 2K mold solutions for packaging, household, kitchenware, baby products, and industrial applications. We combine advanced injection technology with precision tooling to deliver reliable moulds for global clients.

#TwoColorMold #FlipTopCapMold #ChinaMoldMaker #HuangyanMouldFactory #2KMold #InjectionMolding