- Home

- >

- Products

- >

- Household Mold

- >

- Plastic Injection Cutlery Basket Injection Mould

Plastic Injection Cutlery Basket Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Product size: 242.3 X 336.7 X 183.2

Product weight: 265.7g

Core/Cavity Steel: 718H

Product material: PP

Injection: Cold runner

The product is a cutlery basket, but it has a lot of different uses. For example, it can be a picnic basket or cleaning supplies basket. Because the product is plastic, the weight is lighter than other materials, also not easy to break.

Product size: 242.3 X 336.7 X 183.2

Product weight: 265.7g

Core/Cavity Steel: 718H

Product material: PP

Injection: Cold runner

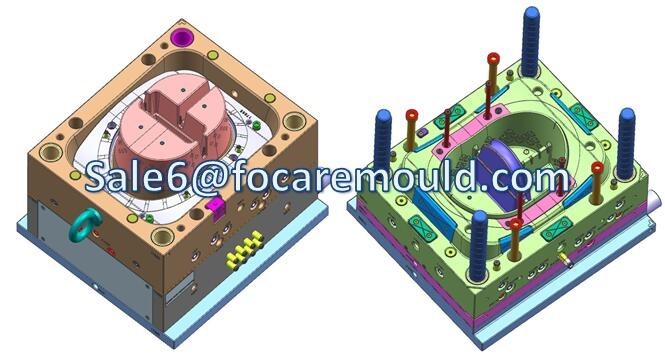

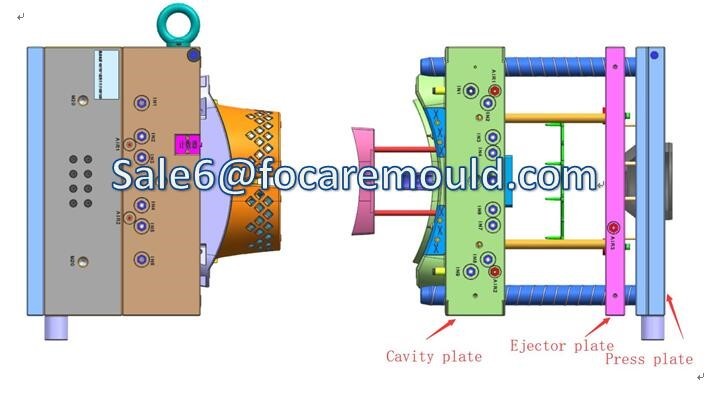

Generally mold design gate is edge gate, but in this mold gate is pin-point gate. After the product is formed the press plate and the cavity are removed by a certain distance, and remaining plastic will fall at the same time.

Since there are holes in the side of the product, there are through holes in the cavity of the mold design structure. Therefore, 2 ejector block in the design of cavity, and then ejector block are driven by the pull hook of the core. Let product stuck in the core, and then ejector by stripper plate of core, last air ejection from bevel, let the product fall smoothly.

Owing to the high cost of using hot runners, if the customer wants to save costs, the product mold design can use cold runner injection molding.

In Focare Mould, you may create your own cutlery basket, and of course, all of the products that have come into your mind.