- Home

- >

- News

- >

- Company News

- >

- The basic principles of two-color mold design

The basic principles of two-color mold design

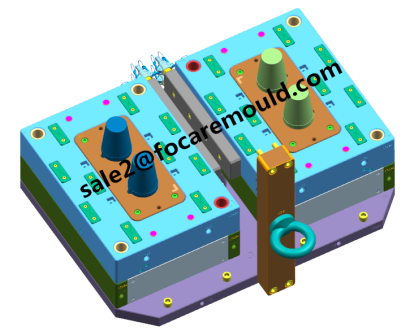

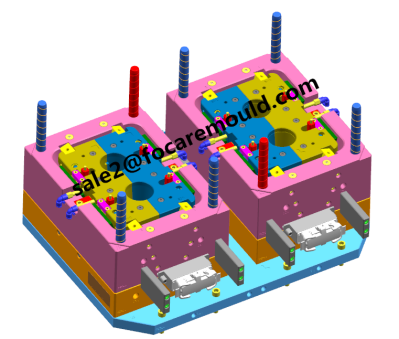

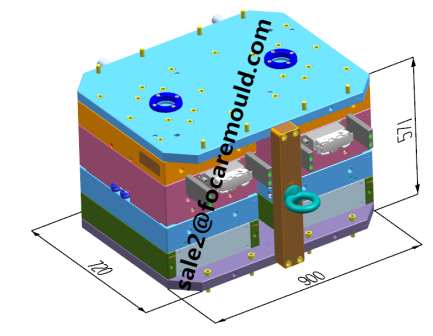

Double injection is two kinds of plastic materials are injected on the same injection machine, forming twice, but the product only comes out of the mould once. Generally, this kind of moulding process is also called double material injection moulding or two-component injection, which is usually completed by a set of moulds and requires a special two-color injection moulding machine. Dual-color dies are becoming more and more popular in the market nowadays. This process can make the appearance of products more beautiful and easy to change color without spraying, but the cost is high and the technical requirements are high.

The basic principles of two-color mode design are as follows:

1. Hard glue once and soft glue twice.

2. Transparent once and opaque twice

The plastics with high forming temperature are made once and the plastics with low forming temperature are made twice.

Above is the basic principle of making two-color die, otherwise the die will be made in vain; in addition, when sealing glue, try to rely on the breaking glue, rather than inserting the breaking glue, even if it is suggested that customers modify the product must rely on the breaking glue as far as possible.

Focare Mould has experienced mold designer and skilled mold workers in two-color injection molds.

Please feel free to communicate with us if you are interested in developing new two-color project.