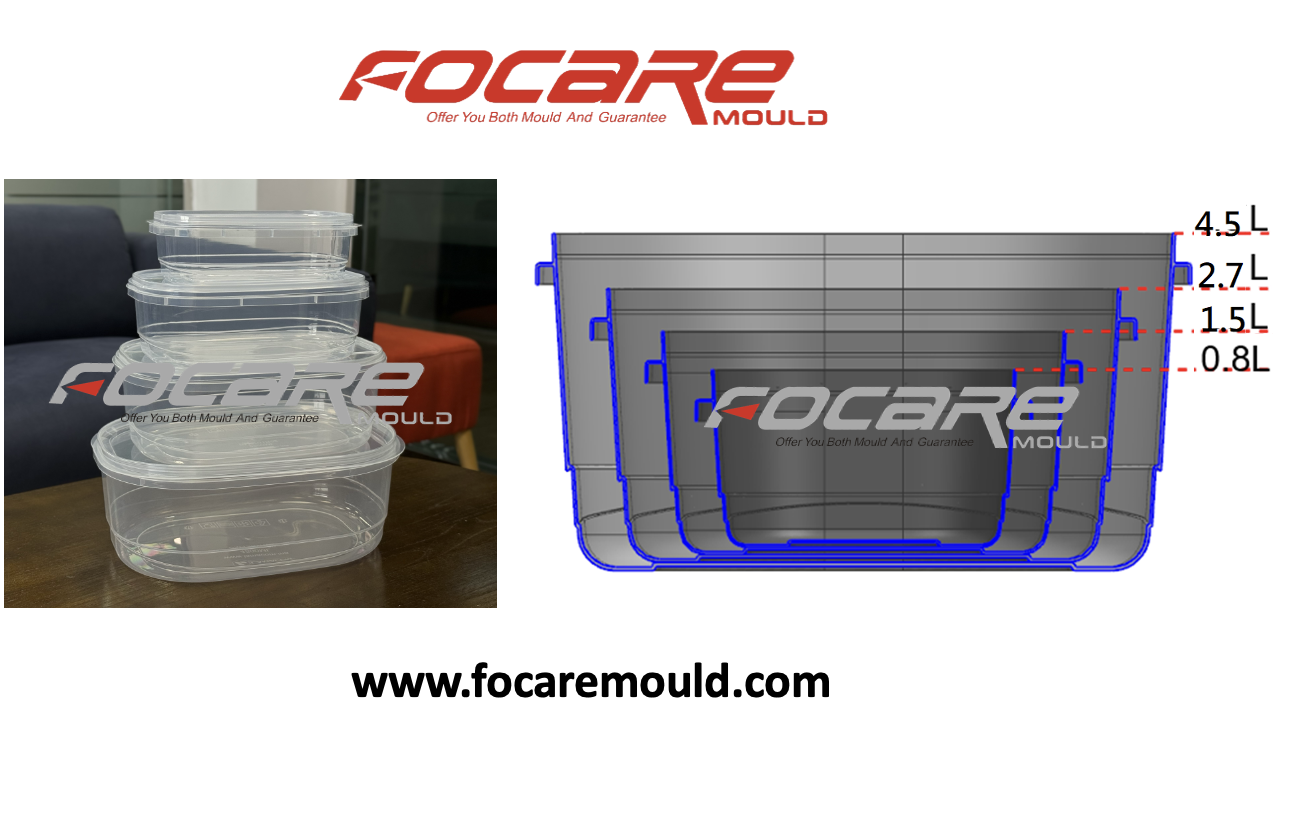

Thin-wall packaging food container mold

Mold Steel:H13 with 48-52 HRC

Mold Injection System: Valve Gate

In today’s fast-paced consumer goods market, the demand for lightweight and durable packaging has skyrocketed. Thin wall packaging containers are essential for industries like food and beverage, cosmetics, pharmaceuticals, and household goods due to their ability to reduce material costs and environmental impact while maintaining structural integrity. Leading the industry in this specialized area is Focare Mould, a prominent China mold maker renowned for their expertise in high-quality thin wall container molds.

What is Thin Wall Packaging?

Thin wall packaging containers are precisely designed to have minimal wall thickness without compromising strength or functionality. Typically, these containers are made from materials like polypropylene (PP) or polyethylene (PE), which provide durability, lightness, and food-safe qualities. Thin wall packaging solutions are often used for items such as yogurt cups, deli containers, ice cream tubs, and more.

The Challenges of Thin Wall Mold Making

Thin wall packaging requires molds that are designed with extreme precision. The molds must be capable of achieving high injection speeds, maintaining consistent wall thickness, and ensuring smooth part ejection to prevent any damage to the thin structure of the product. These specifications require a mold that can handle the pressures and temperatures involved in high-speed injection molding.

At Focare Mould, each mold is developed with these challenges in mind, utilizing cutting-edge technology and materials to guarantee durability and precision. Their experience as a thin wall mold maker ensures that each mold undergoes rigorous testing and optimization, allowing for efficient production cycles and high-quality output.

Key Benefits of Focare Mould’s Thin Wall Packaging Container Molds

High-Speed Production: Focare Mould designs its thin wall molds to accommodate high-speed injection molding machines. This allows clients to increase production efficiency and reduce cycle times.

Durable and Precision-Engineered Molds: The molds are crafted from high-quality materials and are treated to withstand the stresses of high-speed injection. This results in a longer mold life and minimizes downtime due to maintenance.

Optimized Cooling Channels: Efficient cooling is essential for thin wall molding due to the rapid heating and cooling cycles involved. Focare Mould integrates optimized cooling channels within each mold to prevent warping and improve product consistency.

Enhanced Ejection Systems: Thin wall molds must ensure smooth and damage-free ejection to avoid deforming the finished product. Focare Mould’s designs incorporate advanced ejection mechanisms that support flawless part release, crucial for thin-walled items.

Cost Efficiency and Environmental Benefits: By reducing material thickness, thin wall packaging allows manufacturers to lower material costs and reduce waste. Additionally, lightweight packaging contributes to lower shipping costs and a reduced carbon footprint.

Why Choose Focare Mould for Thin Wall Packaging Container Molds?

Focare Mould has established itself as a trusted China mold maker by providing tailored solutions for clients across various sectors. With years of experience and a customer-centered approach, Focare Mould’s commitment to quality and innovation has made it a leader in the field of thin wall mold making. Here’s what sets Focare Mould apart:

Experience and Expertise: With a track record in the mold-making industry, Focare Mould has developed in-depth expertise in thin wall container molds, ensuring that every project meets rigorous industry standards.

Customization: Focare Mould offers customized mold solutions to meet specific client needs, from design to production. This includes working closely with clients to optimize mold designs for their unique product specifications.

Quality Control: Each mold undergoes strict quality control checks to ensure it meets the highest standards of precision and durability.

As industries continue to push for efficient, sustainable, and cost-effective packaging solutions, the demand for thin wall packaging containers is set to rise. By choosing Focare Mould, a leading China mold maker specializing in thin wall mold technology, manufacturers can benefit from reliable, high-speed, and precision-engineered molds that deliver consistent quality and performance.

Whether you’re looking to produce yogurt containers, food trays, or cosmetic containers, Focare Mould offers unmatched expertise and state-of-the-art solutions tailored to the demands of the thin wall packaging market.