- Home

- >

- Products

- >

- Plastic Cup / Mug / Pitcher / Jug Mold

- >

- Plastic Cup Injection Mould

Plastic Cup Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Plastic Cups are containers for drinks and tea. Usually made of PP and PS material. Generally used in beverage stores, hot and cold drink stores, milk tea shops, hotels, restaurants, and coffee shops, which provide a variety of plastic cup drinks to go and on-site.

Plastic Cups are containers for drinks and tea. Usually made of PP and PS material. Generally used in beverage stores, hot and cold drink stores, milk tea shops, hotels, restaurants, and coffee shops, which provide a variety of plastic cup drinks to go and on-site.

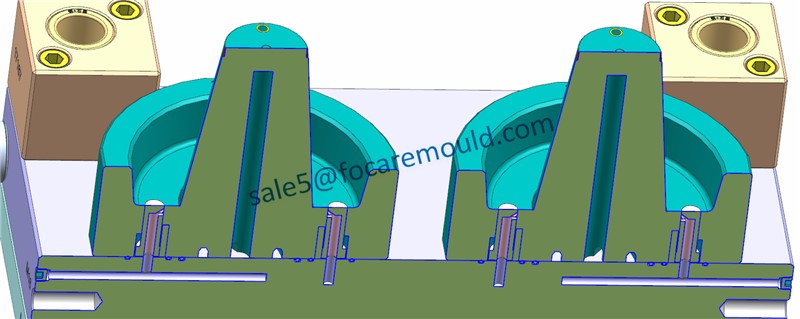

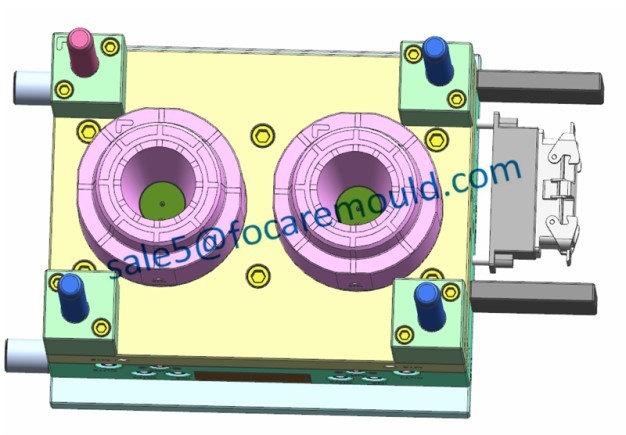

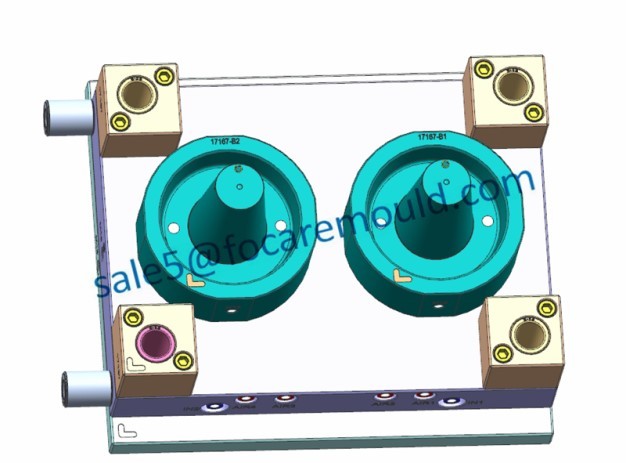

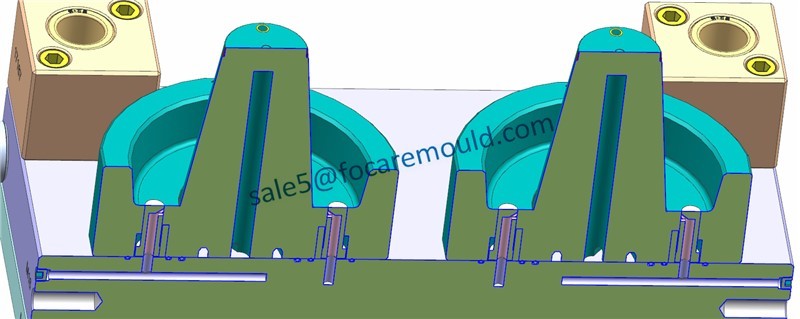

The plastic cup mould is usually been designed in separated cavity molding inserts locking system, the advantage of this is as below:

1. The parts can be processed independently, and the machining precision can be guaranteed. Moreover, quenching heat treatment can be carried out separately. More flexible processing and heat treatment.

2. If the parts are damaged, only the parts need be replaced, so the whole mold will not be scrapped, hence the cost can be better controlled.

3. The materials of each part can be freely selected according to the requirements. Some core parts or some parts that can easily be damaged will be made of high-hardness alloy, which can improve the service life of the mold.

4. Every parts can be disassembled, so the maintenance is very convenient.

For this plastic cup mold, we only use air to blow off the product. So there will be no ejection marks on the surface of the product. At the same time can reduce the amount of mold plate, reduce the height of mold, thus to reduce the cost.