- Home

- >

- Products

- >

- Plastic Chair & Table Mold

- >

- Plastic Chair with Gas Assisted Injection

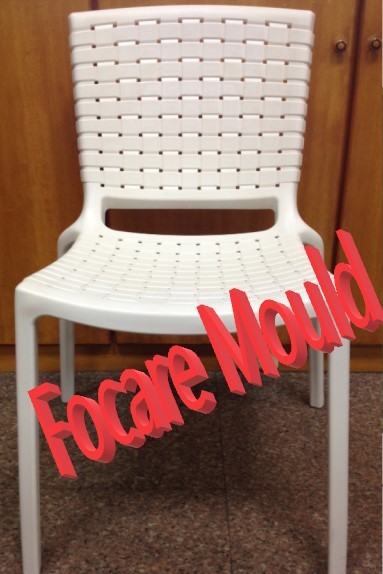

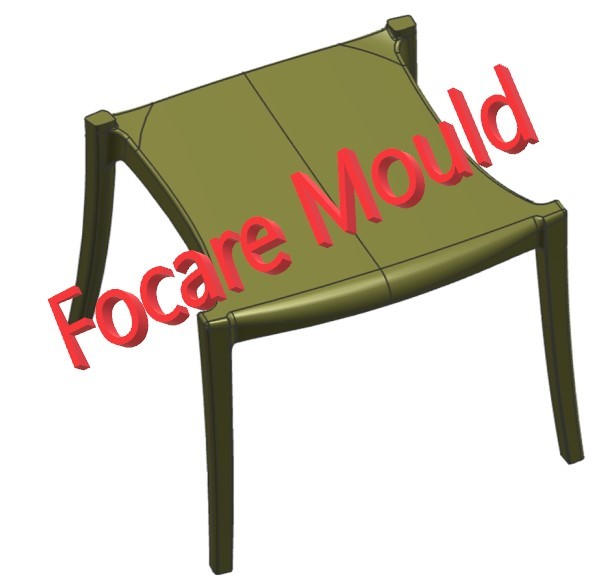

Plastic Chair with Gas Assisted Injection

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Gas-assisted technology offers many possibilities for parts that were previously incapable of being injection molded using conventional processes. Particularly suitable for the production of the following aspects of injection molding: tubular and rod-shaped parts, such as the steering wheel left adjustment lever, car door handle, car rain wipes, rings, hooks, seat armrests, window frames, etc.; large flat parts Such as door panels, automotive exterior parts, radiator grilles, etc.; parts with complex shapes, uneven thickness, and traditional injection molding difficult to form, such as automobile body, bumper, instrument panel, etc.

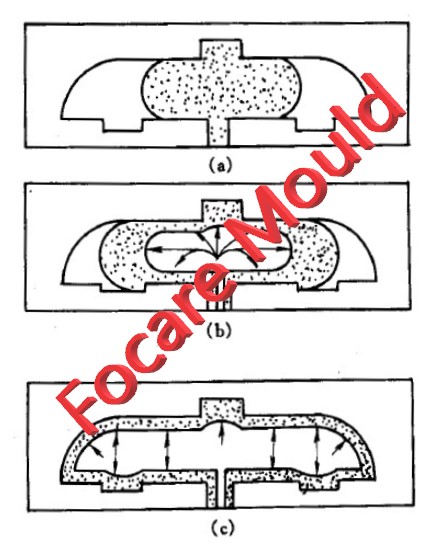

The principle of gas-assisted injection is to create a hollow section in the interior of the injection molded part by high-pressure gas. The volumetric pressure of the gas is used to reduce the residual internal stress of the product, eliminate the surface shrinkage of the product, and reduce the material used, which shows the superiority of the conventional injection molding.

The principle of gas-assisted injection is to create a hollow section in the interior of the injection molded part by high-pressure gas. The volumetric pressure of the gas is used to reduce the residual internal stress of the product, eliminate the surface shrinkage of the product, and reduce the material used, which shows the superiority of the conventional injection molding.

It can form thick and thin-walled composite plastic parts which are difficult to process by traditional injection molding, reduce the number of parts in the assembly structure, thereby reducing the mold, assembly line and labor demand, and the injection pressure required to save production cost is small. On the one hand, small type injection machine can be utilized. Forming large products, on the other hand, the mold material can be replaced by aluminum alloy instead of alloy steel, thereby improving the processing performance and thermal conductivity of the mold parts, reducing the mold cost. The plastic parts are hollow after gas-assisted injection molding, which can reduce weight, save materials, and shorten after forming the mold, the residual stress is small, the warpage deformation is small, and the dimensional stability is good.

Gas-assisted technology offers many possibilities for parts that were previously incapable of being injection molded using conventional processes. Particularly suitable for the production of the following aspects of injection molding: tubular and rod-shaped parts, such as the steering wheel left adjustment lever, car door handle, car rain wipes, rings, hooks, seat armrests, window frames, etc.; large flat parts Such as door panels, automotive exterior parts, radiator grilles, etc.; parts with complex shapes, uneven thickness, and traditional injection molding difficult to form, such as automobile body, bumper, instrument panel, etc.

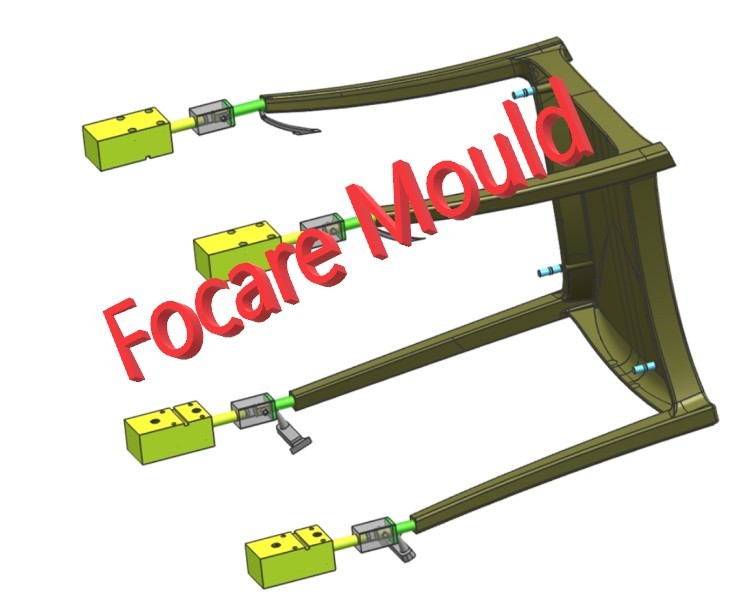

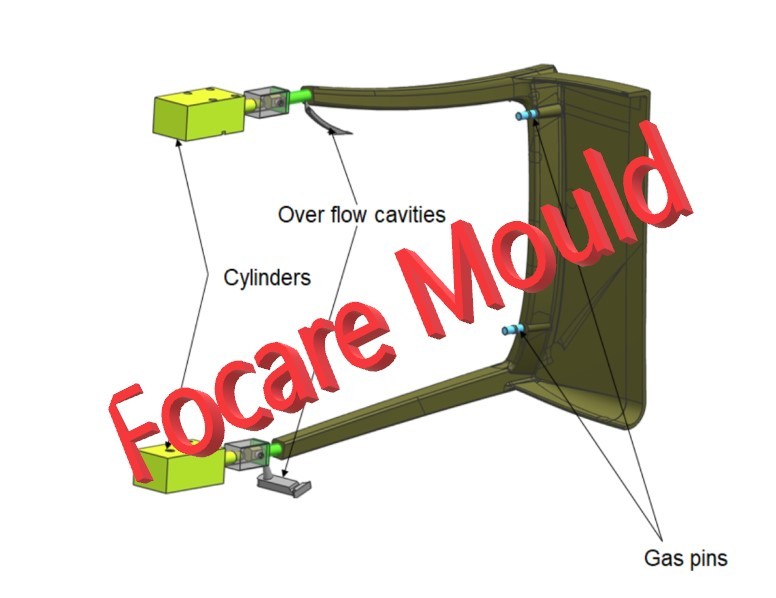

Gas-assisted injection molding equipment

1. Ordinary injection molding machine (the metering accuracy is slightly higher).

2. Nitrogen control system, including self-sealing gas-assisted nozzles.

3. High pressure nitrogen generator.

4. Industrial nitrogen cylinders and air compressors that provide supercharged power.

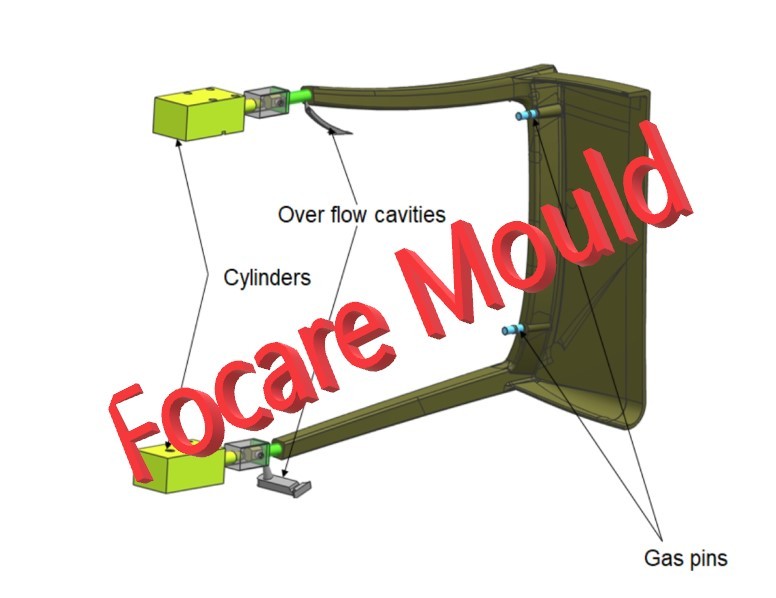

5. A mold designed and manufactured for gas-assisted injection.

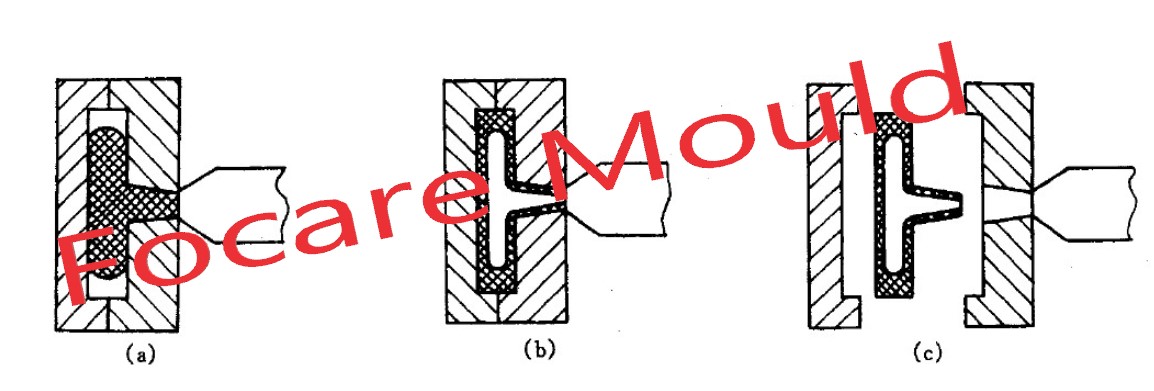

6. Gas-assisted injection molding gas auxiliary nozzle

The nozzle air intake mode uses a special self-closing gas-assisted nozzle. After the plastic injection is finished, the high-pressure gas directly enters the plastic inside by the nozzle, forming an extended closed space according to the air passage—the air chamber and maintaining a certain pressure until cooling. Before the mold is opened, the nozzle is forced to separate from the product channel by the backrest of the table, so that the gas is discharged from the product.

7. Gas needle

The air needle intake method is to install an exhaust device—a gas needle at a specific position of the mold. When the plastic is injected into the cavity, the gas needle is wrapped inside the plastic; at this time, the high-pressure gas is discharged, and the gas needle forms an extended closed space-air cavity according to the air passage inside the plastic, and maintains a certain pressure until cooling, before the mold is opened. The gas in the air chamber is discharged from the inside of the plastic by the control device by means of the gas needle.