- Home

- >

- Products

- >

- Household Mold

- >

- Floor Drain Plastic Injection Mould

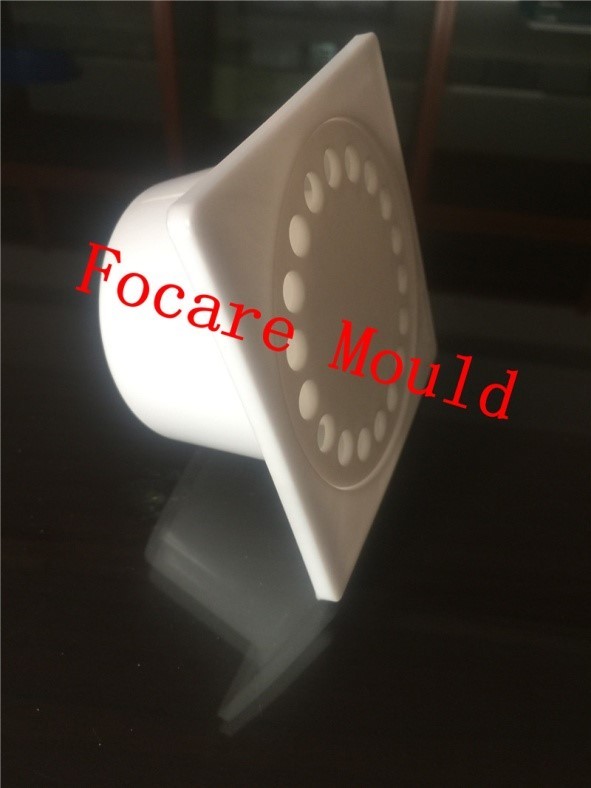

Floor Drain Plastic Injection Mould

Brand :Focare Mould

Product origin :China

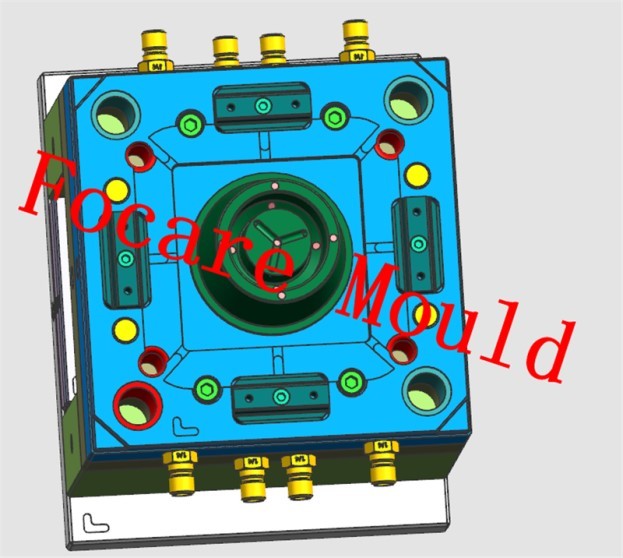

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

This floor drain is made by rigid PVC which mould steel shall be used S136. The steel structure is pure and fine, with excellent corrosion resistance, polishing, wear resistance, machining, and dimensional stability when quench. S136 can be used in all molds. Because of its special properties and materials, it is more suitable for the application and needs of special environment.

Floor drain is an important interface between the drainage pipe system and the indoor floor. As an important part of the drainage system in the house, its performance directly affects the quality of indoor air, and is very important for the odor control of the bathroom.

A good floor drain should have the following four functions: fast drainage, odor prevention, blockage prevention and easy cleaning.

The selection of floor drain has the following points:

1. Water seal is one of the important characteristics of water sealed floor drain. During selection, it is necessary to know whether the water seal depth of the product reaches 50mm. At present, the sealing depth of some ground water leakage on the market is only 10-20 mm, which cannot effectively block the odor of sewer.

2. The height of the floor drain grate surface can be adjusted, and the height shall not be less than 35mm, so as to ensure that the floor drain surface elevation after the completion of the ground decoration is level with the ground. The waterproof protection ring is set for the floor drain to meet the waterproof requirements when it is installed on the floor.

3. The structure of the floor drain with water seal shall be reasonable and smooth, and the sundries in the drainage shall not settle down easily; the cross-section area of each part of the water discharge shall be larger than the cross-section area of the discharge pipe, and the minimum net width of the cross-section of the flow channel shall not be less than 10 mm

Use S136 steel for manufacture the mould.

The steel structure is pure and fine, with excellent corrosion resistance, polishing, wear resistance, machining, and dimensional stability when quench.

S136 can be used in all molds. Because of its special properties and materials, it is more suitable for the application and needs of special environment.

Corrosion and strain resistance:

When using corrosive PVC acetate injection materials or molds, they must be able to resist the corrosion of water vapor, weak organic acid, nitrate, carbonate, etc. when they are working and stored in a humid environment. Molds made by S136 will not rust and be polluted if they are operated in a humid environment or use corrosive plastic materials under normal conditions. If tempered to 250 ℃ and polished to mirror state, it can show excellent corrosion resistance.

Wear resistance:

Using injection molding materials with high friction (including injection molding mold) or requiring a long working time of the mold, such as electronic parts, disposable dining tools, utensils, etc.

High finish surfaces:

Production of optical products, such as cameras, sunglasses, chemical instruments, syringes, analytical instruments and plastic products.