- Home

- >

- Products

- >

- Baby Use Mold

- >

- Baby Walker Plastic Injection Mould

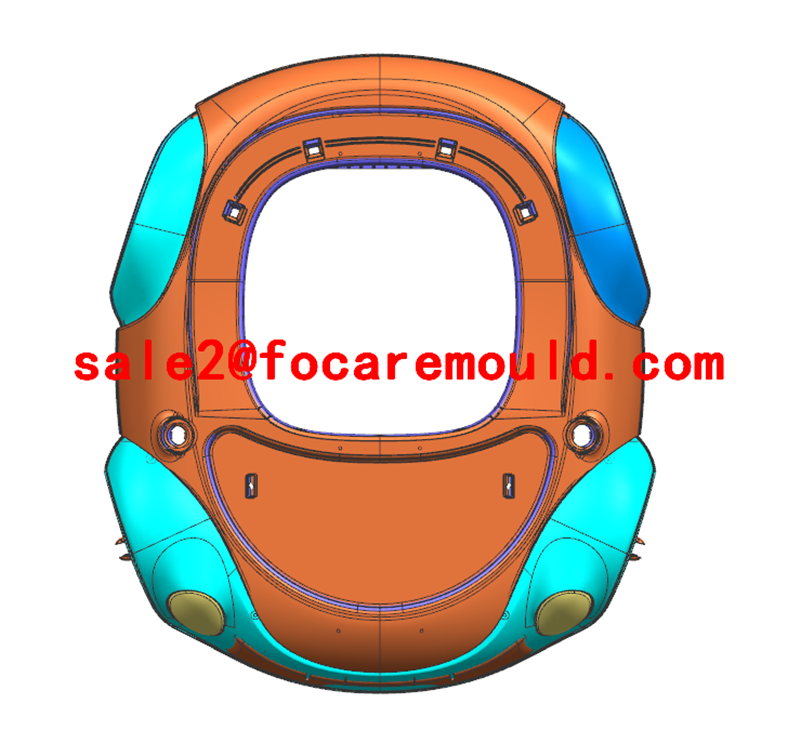

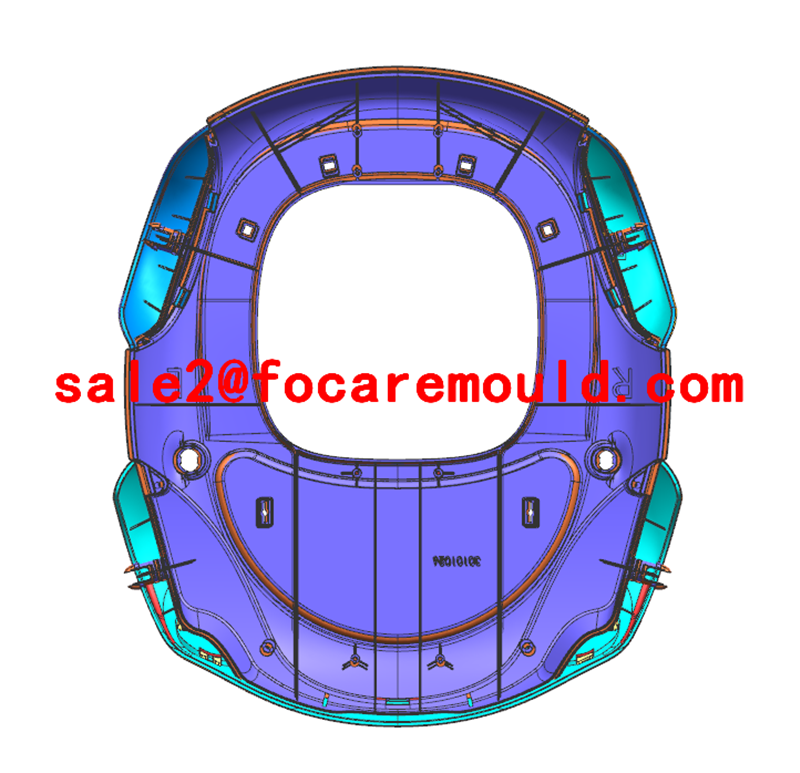

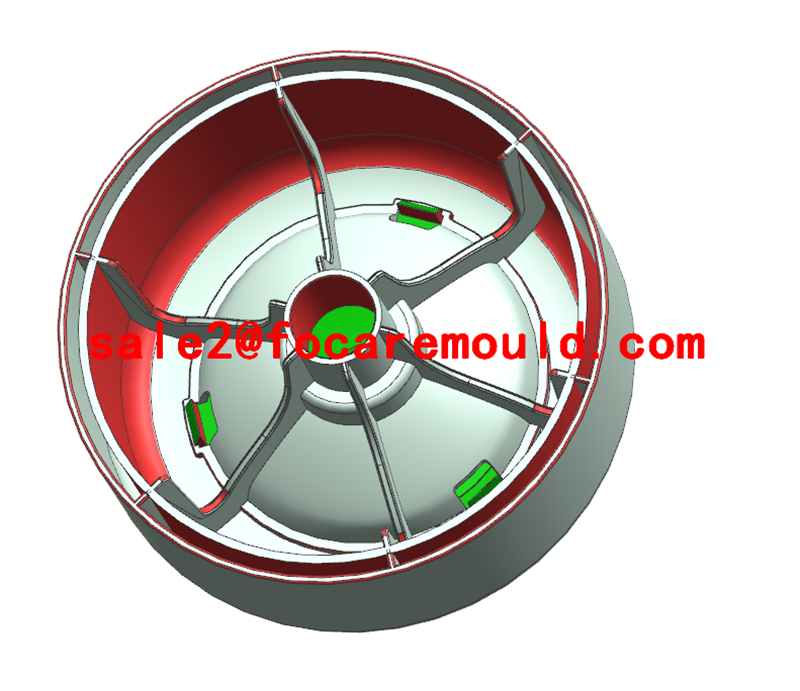

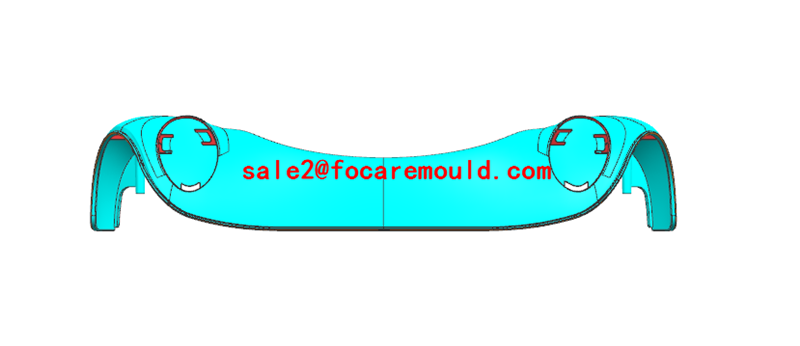

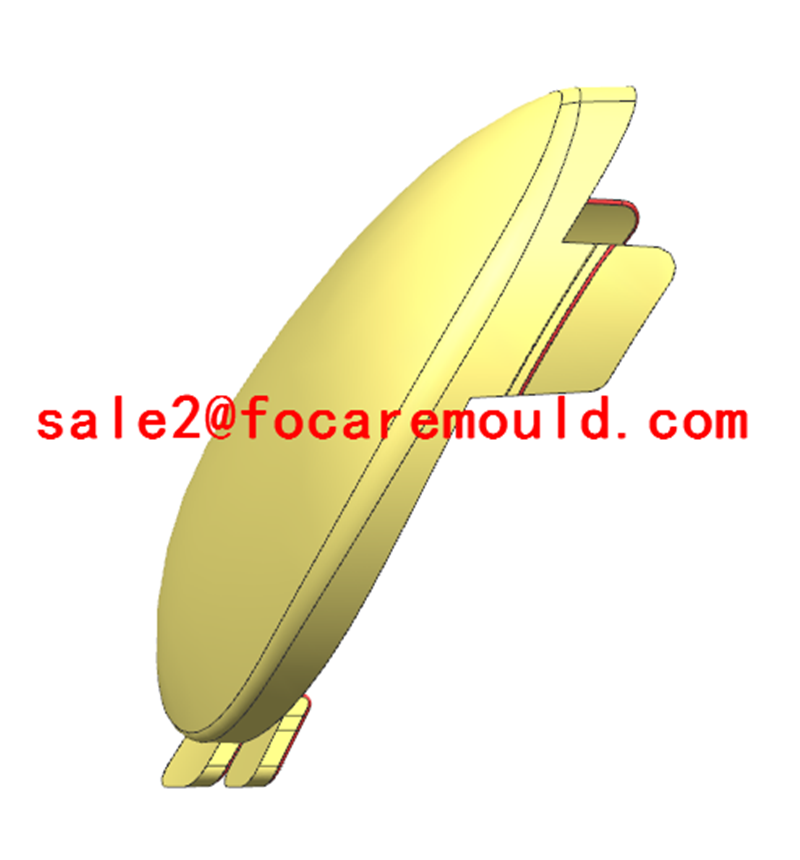

Baby Walker Plastic Injection Mould

Brand :Focare Mould

Product origin :China

Delivery time :60 working days after confirming the design

Supply capacity :500 sets of molds per year

In order to reduce the weight of baby walker, most of parts are made by plastic. On the other hand, plastic parts are stronger and colorful. Therefore, the quality of plastic parts of baby walker become very important. The key point of plastic injection mould for making baby walker is to get smooth surface and parting line to avoid injury against babies. Meanwhile, the assembly among of all plastic parts for baby walker is required flat without difference in level, prevent from collapse, enough strong and so on. It has to pay attention on the shrinkage of molds design and precise mold fabrication in order to get perfect assembly of baby walker, especially the small toy parts.

A baby walker is a device that can be used by infants who cannot walk on their own to move from one place to another. Modern baby walkers are also for toddlers. The have a base made of hard plastic sitting on top of wheels, a suspended fabric seat with two leg holes, round table, toys, chassis frame, and so on.

The Baby walker can help Babies learn to walk properly, which is helpful for the coordination of body movements. On the premise of ensuring safety and correct use, the baby walker provide convenient tools for babies to learn to walk, and also liberate their mother's hands. If the choice of the Baby walker is not suitable, it will also have a bad impact for baby learning to walk.

The mandatory standard for baby walkers applies to devices that are as below:

1. Comprised of a frame on wheels

2. Designed to support, inside the frame, a child with its feet touching the ground and who has not yet learned to walk

3. Propelled by the movement of a child.

In order to reduce the weight of baby walker, most of parts are made by plastic. On the other hand, plastic parts are stronger and colorful. Therefore, the quality of plastic parts of baby walker become very important. The key point of plastic injection mould for making baby walker is to get smooth surface and parting line to avoid injury against babies. Meanwhile, the assembly among of all plastic parts for baby walker is required flat without difference in level, prevent from collapse, enough strong and so on. It has to pay attention on the shrinkage of molds design and precise mold fabrication in order to get perfect assembly of baby walker, especially the small toy parts.