-

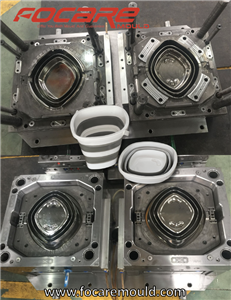

Two Color Collapsible Bucket Mold

Two color 2k double color bi-injection plastic collapsible bucket injection mold Mold Cavity: 1+1 Mold Steel:718H with 30-33 HRC Mold Injection System:4 tips HR Mold Dimension: 900 X 600 X 506 mm

Read More -

Two color 2k foldable bucket mold

Product Material: PP+TPE Mould Cavity: 1+1 Hot Runner system: 3-plate cold runner Mould Steel: Germany 718H Mold dimensions: 1180 X 710 X 510mm Mold size: 2188 kg Suggested machine: FCS-550R

Read More -

Plastic bucket injection mold

Normally, in order to optimize your products, many people choice to use IML (in mold labeling) to have different kinds of products with only one plastic mold. But if you do not have the budget to purchase the IML system (normally one robot, one static generator, and labels), you can also consider to use texture on the surface of the plastic buckets. The texture can be the big logo of your company, the signs of your National culture or any drawings which can catch consumers’ eyes.

Read More -

Plastic foot bath bucket injection mold

With the plastic foot bath bucket, you do not need to spend extra money to do foot bath outside, we can enjoy foot bath at home every day. The design of raised dots on the bottom of the bucket allows us to do simple foot massage while soaking our feet. The wide mouth design makes it easy for us to soak our feet. Besides, the thickness of the plastic foot bath bucket is moderate, and the bucket will not be distorted due to the weight of water which will be happened only when the wall thickness is too thin.

Read More -

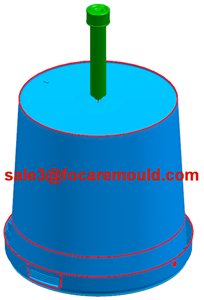

All-purpose bucket plastic injection mold

Normally the size of all-purpose buckets is from 25L to more than 210L. But we made this all-purpose bucket with the size no more than 0.5L. We can consider this all-purpose bucket as a toy for kids, company giveaway or storage bucket for desk for storing candies, paperclips, Elliot folders, etc. It can help you to organize your working desk.

Read More -

Plastic paint bucket injection mold

There are several methods to test plastic paint buckets: 1. Airtightness test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, the bucket should be dumped. The lid should not fall off or leak. 2. Push-down test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, stack three buckets together, tilt them and let the buckets fall; the bucket lid cannot be opened. 3. Drop test: After assembling the matching lid to fill the plastic paint bucket with 80% of water, drop it at an inclined angle of 45 ° at the bottom of the bucket at a height of 80cm. The lid cannot be separated from the bucket, and the bottom of the bucket must not be broken. 4. Special test: After assembling the matching lid to fill the bucket with 80% of water, stack 4 buckets without deformation for 7 days. 5. Side leak test: Fill the bucket with 80% of water and leave to stand for 30 minutes without leakage; turn to the opposite side for 30 minutes without leakage.

Read More