- Home

- >

- Products

- >

- Kitchenware Mold

- >

- Disposable Cutlery Mold

- >

- Disposable knife plastic injection mould

Disposable knife plastic injection mould

We maximize the efficiency of cooling system and eject system. 10 water channels and almost 100 ejector pins are applied in the disposable knife plastic injection mold. The cycle time is 12 seconds, which means 200 disposable knives are produced in one minute.

As the pace of life is so fast, people get so busy that we seldom have time or chances to cook. Ordering take-out has been regarded as a way to improve efficiency of life. The demand of disposable tableware has substantially risen especially in the economically developed areas.

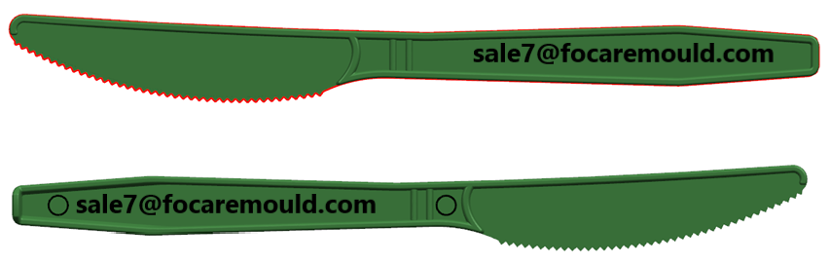

The disposable knife is made by PP, 2.6g. It is light but strong. To reach the maximum efficiency, high productivity, manufacturers have to minimize the product weight and cycle time. Therefore, the selection of plastic injection machines and plastic injection mold suppliers becomes the most important thing.

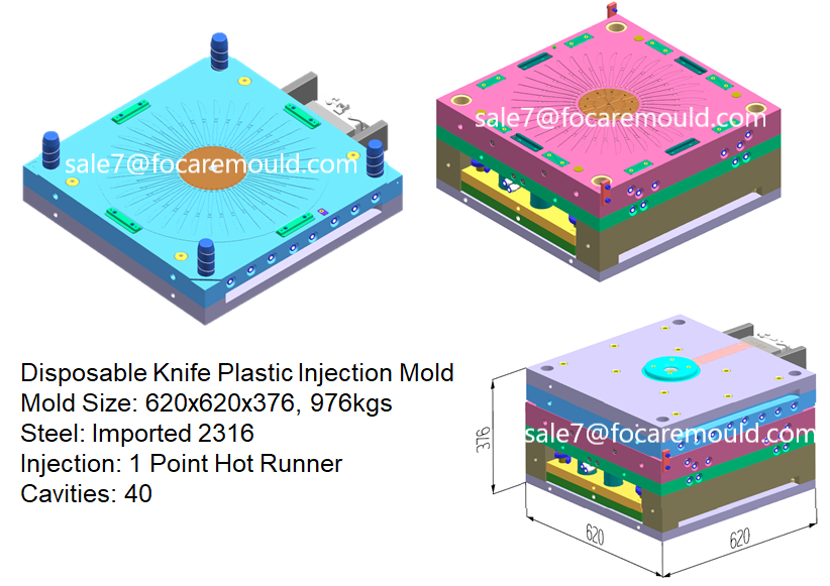

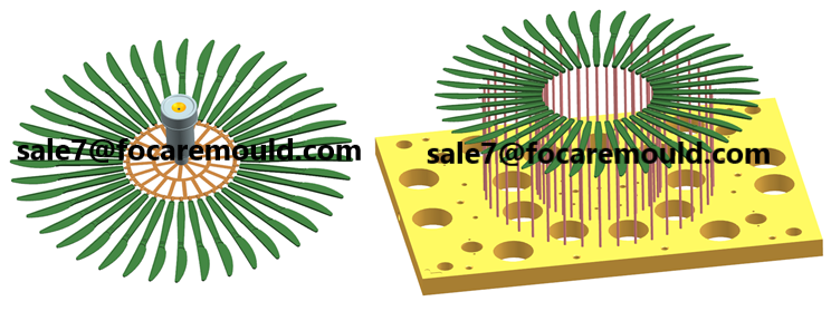

For the disposable knife plastic injection molds, Focare Mould, we designed it as 40 cavities, whose size is 620 X 620 X 370 mm and the weight is 976kg. We use imported 2316 for its steel, the HRC is 45~48, and one point hot runner gate and 40 small circularly distributive gates.

Here are some reasons of Focare Mould being so trustworthy that the same customer has ordered for sets:

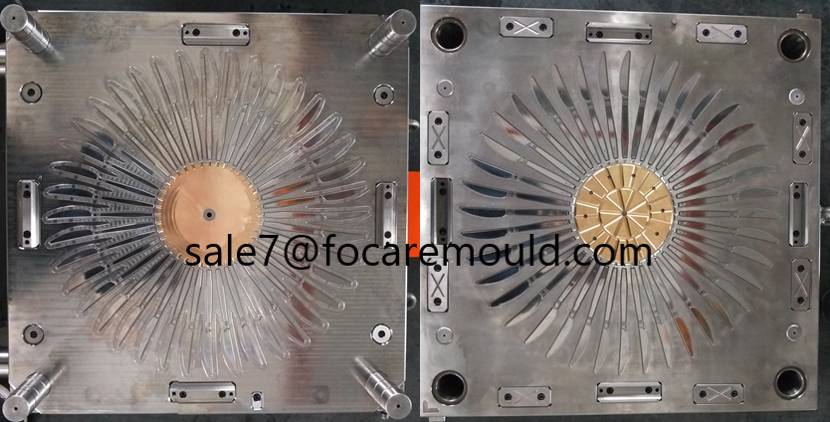

1. We made injection gate and the runner as an insert, which can be replaced or modified easily, also it allows disposable knives to automatic break with runner.

However, if your production is automated, we can adjust the size of distributive gates that products will be produced by set. Therefore, you can produce, cut, and pack the products efficiently.

2. We adopt BeCu as steel. BeCu has high hardness, elastic limit, fatigue limit, wear resistance, corrosion resistance, and thermal conductivity. It makes the material runs more smoothly, and faster.

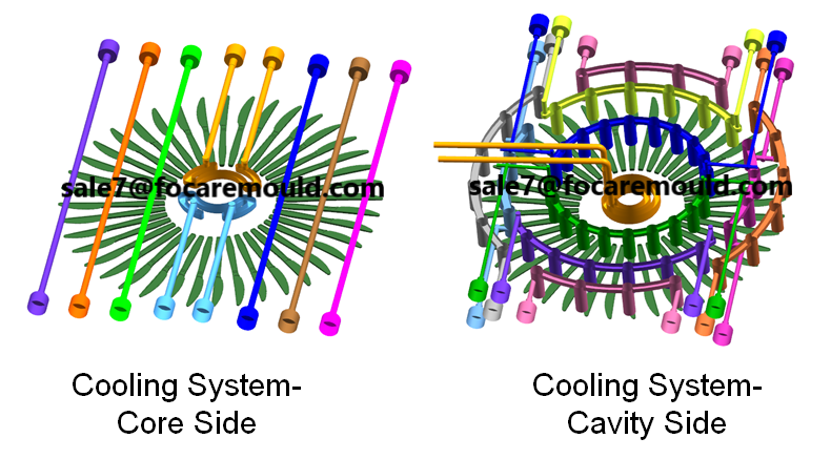

3. We maximize the efficiency of cooling system and eject system. 10 water channels and almost 100 ejector pins are applied in the disposable knife plastic injection mold. The cycle time is 12 seconds, which means 200 disposable knives are produced in one minute.

4. The accuracy of the mold is highly required, due to the product is thin and one side is saw-toothed. Focare Mould, we are able to control the precision of our mold within 0.01mm.

5. We are also very caution on details. For example, we will assemble weld plates on the part which is likely to be fractioned. The HRC of weld plates is up to 48~52.

6. We mark every plate for correct and faster replacement if the steel is broken in the future.

7. Instead of using standard bearings and ejector guide bush, we adopt ones with steel ball inside for more stable mold movement, reduce the vibration of transmission between components which can prolong the use-age of mold, and promote high operating efficiency.

Welcome to contact us for more information, and you will know what Focare Mould can provide is far more than others.