- Home

- >

- Products

- >

- Household Mold

- >

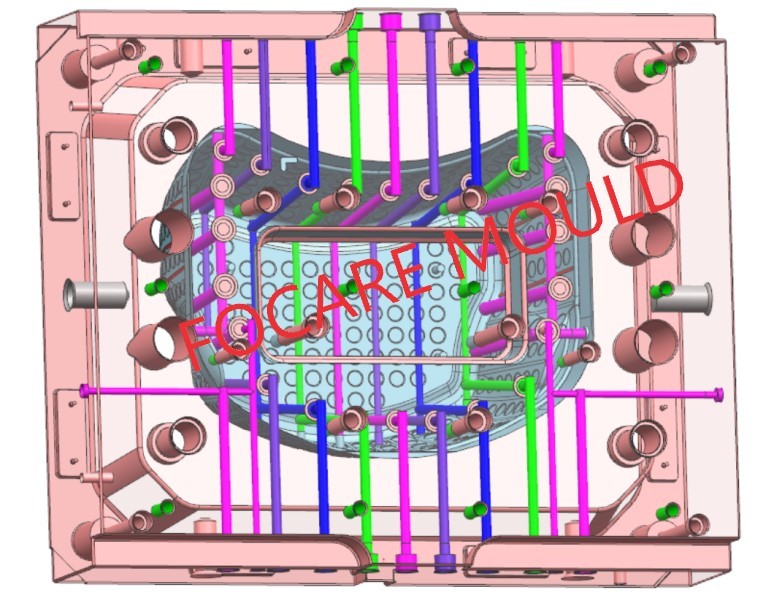

- 48L Laundry basket Plastic Injection Mould

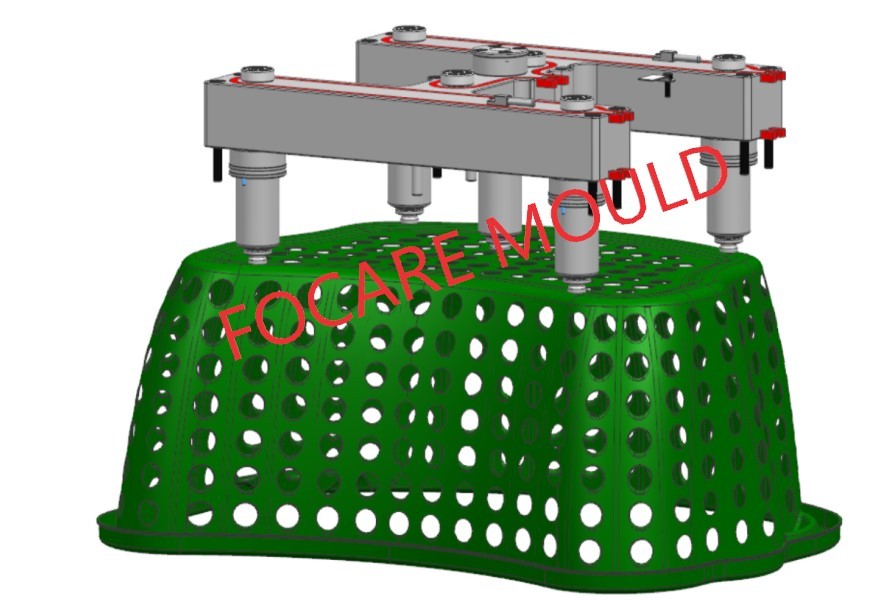

48L Laundry basket Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

Laundry Basket Size: 489.2 X 622.7 X 233.9mm

Basket Weight: 0.59 kgs

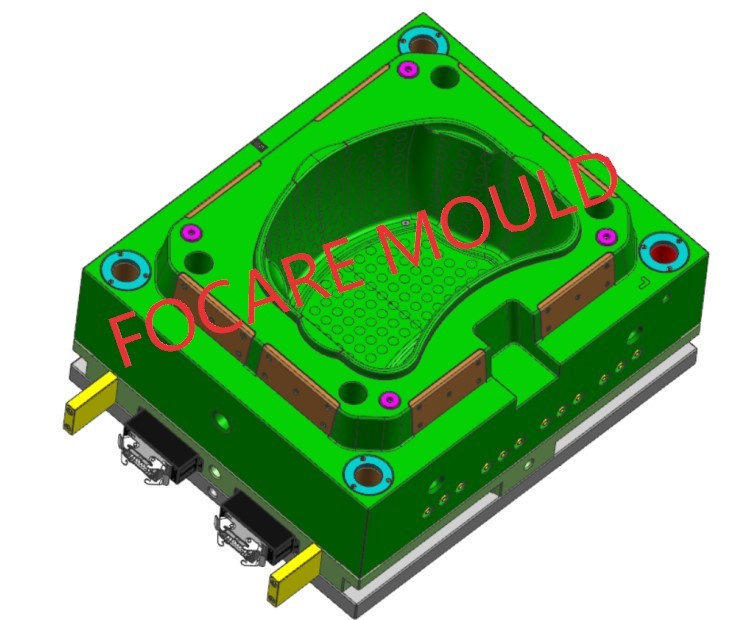

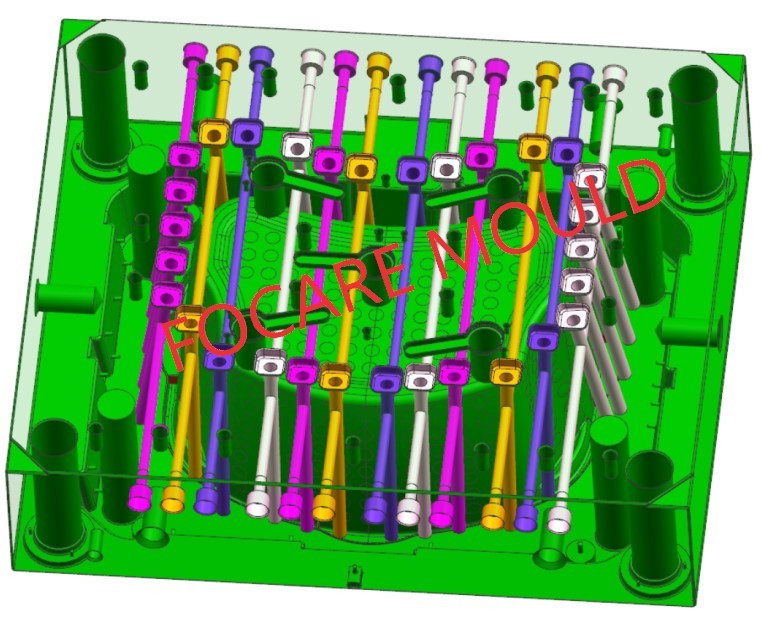

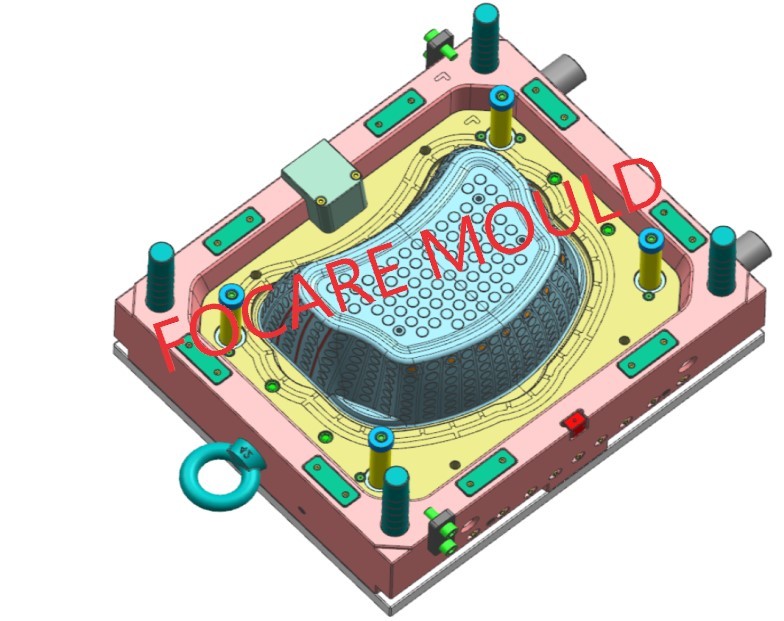

Gate system: 5 tips Hot Runner

Not all molding applications are suitable for runner-less molding. Some materials are heat sensitive and the time to temperature relationship - especially when the shot size is very small - can be a problem. Some families of parts, for handling and orientation purposes, may be best kept attached to the runner until they reach another downstream operation. In other instances, the required volume of parts may be so small that the added cost of the hot runner system to the mold price cannot be justified.

This laundry basket mold is designed with 5 hot runner tips.

Not all molding applications are suitable for runnerless molding. Some materials are heat sensitive and the time to temperature relationship - especially when the shot size is very small - can be a problem. Some families of parts, for handling and orientation purposes, may be best kept attached to the runner until they reach another downstream operation. In other instances, the required volume of parts may be so small that the added cost of the hot runner system to the mold price cannot be justified.

Hot Runner Advantages

Although there will be an ongoing need for cold runner molds, the advantages of using hot runner systems are so great that they will increasingly be the runner technology of choice for molds used in molding thermoplastics. The key advantages are:

Elimination of the Runner

With materials becoming more sophisticated and expensive, the cold runner becomes, in turn, expensive scrap. Whether or not the runner can be reused - and in many medical and food applications they can't - regrinding and storing the runners is costly, noisy and dusty. In high-speed, high-cavitation molding operations, the scrap and regrind would be huge problems. When using hot runners, these regrind problems and their associated costs are non-existent.

Cycle Time Reduction/Lower Processing Costs

In many cases, the weight of the cold runner is up to half the total shot weight and usually much thicker in section than the molded part wall thickness. Doing away with the cold runner will reduce the cycle time since cooling time is controlled by the thickest section. In addition, there will be further cycle timesavings in the injection screw recovery and injection times because of the smaller shot size.

Improved Molding System Efficiency

Hot runner molds are generally easier to start because there aren't any solidified runners to be removed after each under-filled shot until a full mold shot is achieved and automatic cycling can begin. In hot runner systems, the mold is ready to run when the system reaches operating temperature. Also, with hot runner systems, lower injection pressures can generally be used, which will reduce mold and platen deflection and keep flash caused by mold component movement to a minimum.

Optimal Part Quality

Eliminating the cold runner will give better filling and packing conditions. When plastic is flowing through the cold runner, it loses heat to the mold plates - causing pressure drops that can result in sink marks and under-filled parts. Hot runner systems, on the other hand, maintain a balanced melt flow at a constant temperature from the machine nozzle all the way to the gate to fully fill and pack the cavities. Hot runners, therefore, help molders take full advantage of highly accurate and interchangeable cavities to achieve plastic part dimensional accuracy and quality. Should a cavity get damaged or be out of specification for whatever reason, it is very easy to reduce the heat to its hot runner nozzle and stop the cavity from producing faulty parts.

Molding Automation

An ever-increasing number of companies are automating their plastics molding and assembly. This, in turn, is driving the need for very accurate, flash-free plastic parts. Hot runner molds have a definite advantage when used with automation because, in addition to part dimensional consistency, there are no runners present to get tangled in the mold mechanisms, robots, conveyors, assembly machinery, etc.

Design Flexibility

A major hot runner advantage of which very little is written is the ability to locate the gate at a wide variety of points on the part. With the use of hot tip gating, valve gating or edge gating, hot runners allow the gate to be placed at the most favorable location for optimum filling and/or part aesthetics. This flexibility that hot runners give the part design also extends to the mold, where flexibility in gate location can help optimize cavity orientation, cooling and mold simplification.

Balanced Melt Flow

The flow advantage that hot runners have is that the melt channels are in separate, externally heated manifolds, which are insulated from the surrounding mold plates. Different to a cold runner plate, the hot manifold can be designed to have flow channels on multiple levels to ensure that the resin flows the same length from the molding machine nozzle to each cavity with the same channel profiles and diameters, number of turns, heat soak and pressure loss (see Figure 1). In other words, the plastic reaches each cavity - whether there are two or 96 - with the same pressure and thermal history. This designed-in temperature and pressure control is particularly favorable for resins that have narrow processing windows.