-

Two-Color Plastic Football Cup Injection Mould

This two-color plastic football cup is one of the most popular two-color injection molds at Focare Mould, especially the customers who are very fond of football. Its appearance is more beautiful than single color one. Besides, one can have more design idea by using the obvious color separation. From the transparent window of small circles, you can see a lot of football which let life feel colorful and pleasant.

Read More -

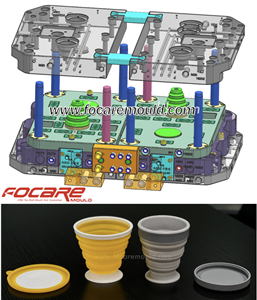

Two-color Plastic Foldable Cup Injection Mold

Product information Material: PP+TPE Body: DIA 92 mm x 82 mm Lid: DIA 94 mm x 7 mm Weight: 52g

Read More -

Straw Handle Cup Plastic Injection Mould

This straw handle cup is divided into two sets of molds, one is the cup body and the other is the cup cover. In design, the cup body cavity 2 spring block slides. When opening the mold, it depends on the pull hook on the mold core side to start in an instant, and then the spring pushes the spring block out, and the mold core side directly relies on the machine to push the ejector plate to eject the product and drop. When the cup cover is opened, slide the 2 sliding blocks on one side of the core to both sides through the inclined guide post to separate the sliding blocks from the product. The 2 sliding blocks are designed on the pusher plate to eject the product as a whole.

Read More -

Plastic Cup Injection Mould

Plastic Cups are containers for drinks and tea. Usually made of PP and PS material. Generally used in beverage stores, hot and cold drink stores, milk tea shops, hotels, restaurants, and coffee shops, which provide a variety of plastic cup drinks to go and on-site.

Read More -

Double Color Romantic Cup Plastic Injection Mould

Please refer to this romantic double color cup, which is designed for making by two-color rotary injection mould. The technological key-point is the logo or totem which customer would like to make with double color injection. If the totem is tiny, small or complicate, it is not only for making double color plastic injection mould, but also for two-color injection.

Read More -

Double Color Plastic Gradient Cup Injection Mould

It is double color product, why the cup look three color? In addition to the material PP+PP, we have also added to special color master to let double color cup become gradient color. Meanwhile, the thickness of double color plastic cup is also designed different from standard cup.

Read More -

Two-Color Bathroom Mug Plastic Injection Mold

A bathroom tumbler is a glass or cup or mug that is kept in the bathroom for teeth brushing, water scooping or other uses. With the advent of the paper cup and an increased awareness of disease prevention, the modern tumbler is often a decorative accent rather than a useful item. That’s why two-color cups become popular day by day.

Read More -

Two-Color Plastic Gargle Cup Injection Molds

This two-color mug mold adopts hot runner technology to eliminate the flow channel aggregate and realize production automation; the cavity adopts the conventional waterway, and the core adopts the conformal waterway design.

Read More -

Clear Plastic Injection Molds of Jugs, Wine Cup, Salad Bowl, Cup and Plate

Clear plastic injection molding parts usually made in GPPS, PC, PMMA(Acrylic), AS(SAN), PET, Tritan and so on. Due to the high light transmittance, clear plastics must have strict requirements on the surface quality of plastic products, without any markings, pores, and whitening. Defects such as haze, black spots, discoloration, poor gloss are not acceptable. Since most of the transparent plastics have high melting point and poor fluidity, it is often necessary to make suitable adjustments to the process parameters such as mold temperature, injection pressure, injection speed, etc. in order to ensure the surface quality of the product. Meanwhile, the surface of mold cores & cavities is required high mirror polishing to get shiny and clear products. High hardness of mold steel is necessary to avoid scratching during ejection

Read More